Hardboard Workbench Top Finish

This past week i decided to replace the original top to my large 4 x 8 assembly table.

Hardboard workbench top finish. I have 2 35x8 workbenches topped off with hardboard countersink wood screws into the surface every 6 8 and 2 away from the edge all the way wound it. This forum is devoted to discussions about shop setup layout and design. Hardboard is great for workbench tops. Pictures of members shops are welcome and encouraged.

Make it the size of the top and attach it with some thin doubles sided carpet tape of some contact cement. I actually worked at lv for the christmas season so am familiar with the products they have. I dont have a problem with it at all. Steve ramsey woodworking for mere mortals 3225949 views.

It puts a thin protective film down that will help keep glue paint and other gunk from sticking to the workbench top. An easy solution is to make a top sheet from 14 hardboard masonite. Finishing hardboard work top thanks to all re. And a few in the middle.

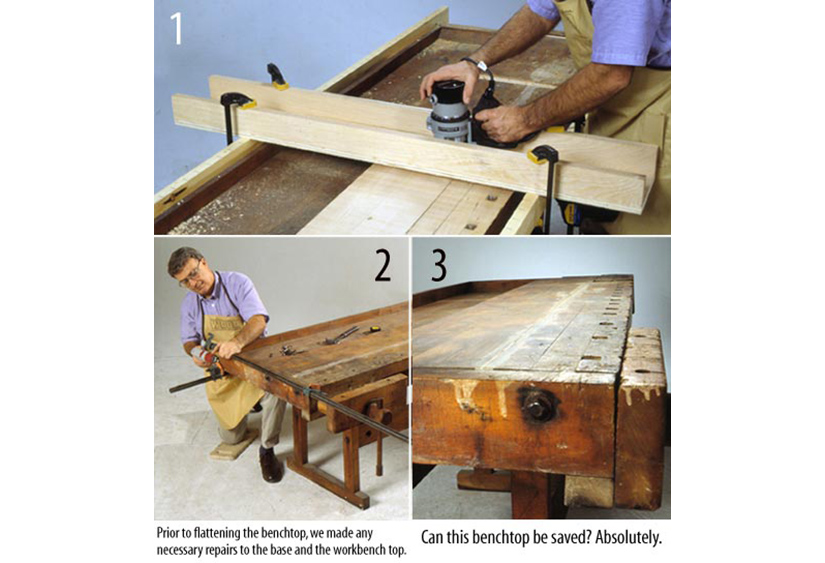

If youre going to use a polyurethane finish or 2 part that will seal the wood then cover both sides of the tabletop with the finish. Let it cure completely. For anyone out there wondering how to spiff up a workbench the right way heres a little advice from two expert woodworkers. My workbench has a hardboard top with several coats of poly.

I would recommend a drying oil finish something like a watco danish oil. The top is edge joined 34 x 3 x 24 hardwoods of various species. Im just about done with building my workbench. The top will be installed for a relative and not be easily accessed to replace the top when required therefore i will try the polymerised tung oil from lv.

Wood finishing basics duration. As to finish i prefer an oilvarnish mixture. Topics here include wiring wood and tool storage floorplans dust collection and basically all the infrastructural stuff not directly related to specific projects and tools. What kind of finish should you use.

There are pros and cons to both but i chose mdf this time. What kind of finish would you recommend for a workbench top made of softwood. The torsion box workbench top is complete. If you just do the work surface and leave the underside bare because you dont see it then the table top could warp due to difference in water absorption release rate between one side and the other.

I decided to use mdf instead of hard board.