Grinding Wheel Grit Size

In other words higher numbers translate to smaller openings in the screen the grains pass through.

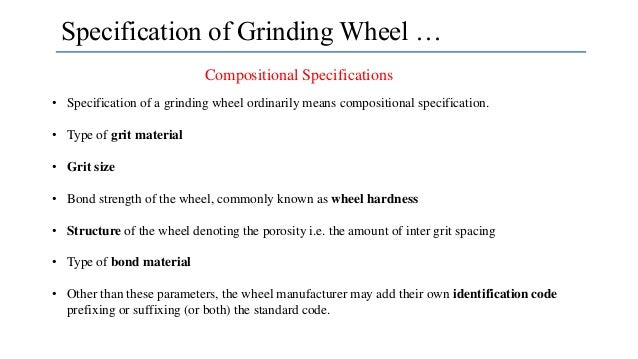

Grinding wheel grit size. As a general guide the harder the material the softer the grade of wheel required. The grit or grain is used to indicate a general size of abrasive for making a grinding wheel. Grinding wheel grit chart grit size and surface finish. A grinding wheel is a wheel composed of an abrasive compound and used for various grinding abrasive cutting and abrasive machining operations.

The wheels are generally made from a composite material consisting of coarse particle aggregate pressed and bonded together by a cementing matrix called the bond in grinding wheel terminology to form a. If you require to perform lapping and polishing please indicate them to us we will quote you. It corresponds to the number of openings per linear inch in the final screen size used to size the grain. Imagine grits grainsof say 116inch or 2 mm would have difficulty making a 016 or 5mm or smaller corner.

Grit or grain of grinding wheel. Once the grain is known the next question relates to grit size. More questions about grit selection ask for help. Grits or grain size is denoted by a number indicates the number of meshes per linear inch of the screen through which the grain pass when they are graded after crushing.

Grit chart of grinding wheels brian zhao 2019 12 25t0925090800. Coarser grit size enables higher material removal rate and rougher surface finishing while a fine grit size is used for attaining a smoother surface finishing. Introdution of gritgrain sizes for diamond and cbn abrasives author date201268 34238 grain size will affect the grinding efficiency and roughness of work piece directly generally speaking if grain size is fine the ground surface of work piece will be less rough while if grain size is coarse the removal of work pieces is more. Grit size typically runs from coarse 16 24 grit medium 36 60 grit and fine 80 120 grit.

Grit size is the size of individual abrasive grains in the wheel. Honing stones and jointing stones and other polishing abrasives will be 150 grit and higher. The chosen grit size affects the performance of the wheel it determining the stock removal rate and surface finish that can be achieved. Grinding wheels usually will be between 24 and 100 grit.

Grit grain size wheel selection often relates to surface finish and ability to make a smaller inside corner or tight form. Every grinding wheel has a number designating this characteristic. For this reason finer grit sized wheels are required to grind hard materials and soft materials are best ground with medium to coarse grit size wheels. Superfine grits run from 150 and higher.