What Is A Bevel Cut Used For

A sliding bevel or a sliding t bevel is a gauge that is completely adjustable typically used to transfer angles.

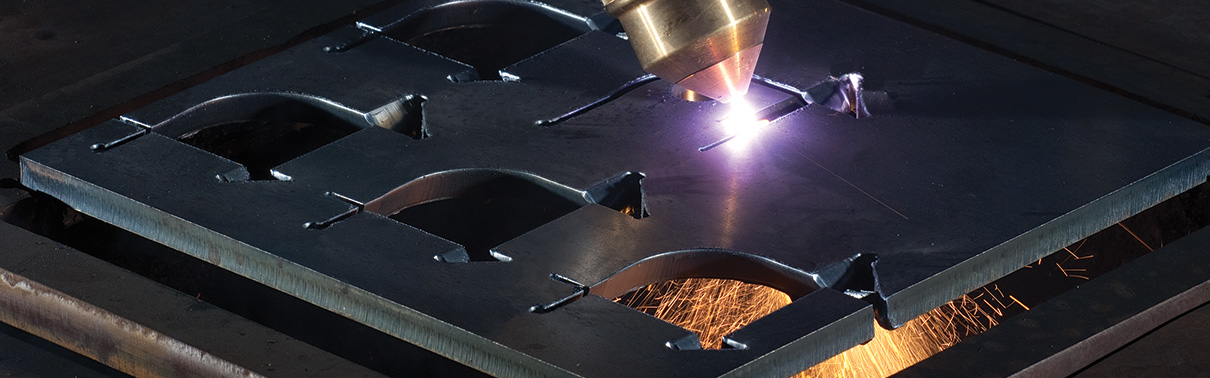

What is a bevel cut used for. One of the ways by which you can distinguish a miter cut from a bevel cut is to identify where the cut has been made. In architecture and design a bevel rule or sliding bevel is a tool that is used to measure and draw angles. The bevel provides a smooth clean edge to the plate or pipe and allows a weld of the correct shape to prevent center line cracking to join the separate pieces of metal. A bevel cut is used to do decorative finishing techniques give additional support for welding and also increase an edges surface area.

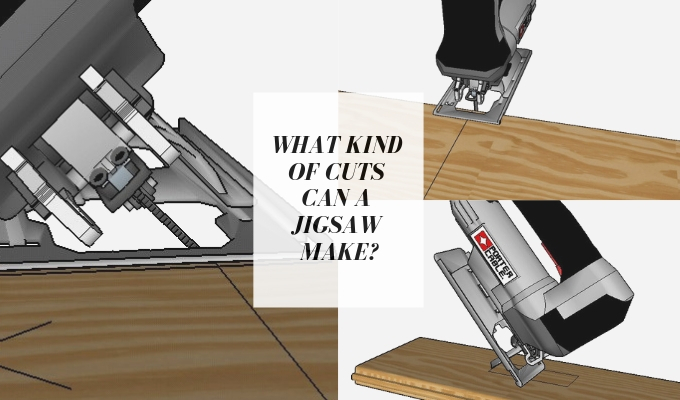

Thus unlike the miter cut a bevel changes the angle of the board edge. To make a bevel cut the blade should be angled through the vertical plane. The control is graduated to tell you the blade angle but the scale isnt always accurate so its best to check the blade angle with a protractor or a bevel which is a tool that carpenters use to measure angles. The pitch surface of bevel gears is a cone.

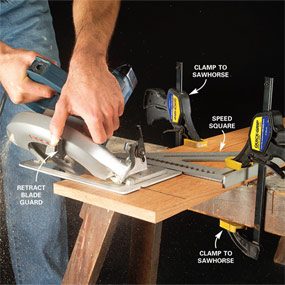

Make a bevel cut using a miter saw with the help of a woodworking professional in this free video. Once your angle is set lock it in place and youre ready to cut your bevel. Angles are also used in jewelry cutting to bring out the brilliance of a stone. To make a bevel cut with a table saw you first change the blade angle from 90 degrees to the desired bevel angle using the angle adjustment control on the front of the saw.

How to tell which is which. Citation needed simple bevels can be used with a backup strip thin removable sheet behind the plate joint with chamfers and a small land being used on open root welds. A miter saw is used for miter cuts but it can also perform bevel cuts. The bevel angle is set behind the handle.

A bevel is used as a decorative finishing technique. Diamonds may have multiple bevels for example creating a highly refractive surface which causes the stone to sparkle. Bevel gears are gears where the axes of the two shafts intersect and the tooth bearing faces of the gears themselves are conically shapedbevel gears are most often mounted on shafts that are 90 degrees apart but can be designed to work at other angles as well. Parallel vs non parallel.

A miter is the angled cut for joining two pieces of material. This makes the top part of your saw mobile. I will use some 24 drawings to illustrate the difference in the cuts. 45 degree miter 45 degree bevel bevel vs miter.