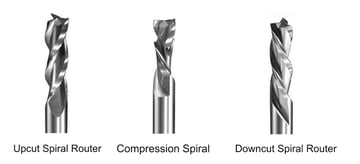

Upcut Vs Downcut

Choosing between up and down cut router bits is one of many things in woodworking that can be frustrating until the reasoning behind the design difference is understood a little better.

Upcut vs downcut. Up cut router bits vs down cut router bits. 432 what is the difference between upcut and downcut bits. Down cut router bits choosing the right one text photos by tom hintz. Upcut vs downcut spiral.

Tool selection is criticial when it comes to achieving a desired surface finish tool life or cut speed for a specific material. There are so many options out there for router bits that it may be difficult to decide which one is the right router bit for your application. Otherwise between the bit getting overheated and the fine paper dust like waste being pushed back into the cut theres a high potential of starting a fire. The cutters of a straight bit do not overlap so if you plunge straight down deeper than 332 in you might burn away the wood in the middle but you wont cut it.

Because a spiral bit is designed much like a drill bit it makes plunge cuts easily. Posted on monday october 6th 2014 at 325 pm. Upcut versus downcut router and your cnc operation jun 28 2017. Compression spirals always leave a witness line in the transition area between upcut and downcut sections of the spiral which may or may not be acceptable i have to concur with you on the need for vacuum extraction of waste.

So how do you decide on an upcut vs. Spiral router bits are made of solid carbide using the technology of metalworking industry. 657 specific applications for spiral upcut bits 1016 why a spiral upcut bit with a bearing. 1213 specific applications for spiral.

As a result the spiral bit is incredibly sharp and swiftly cut through soft or hardwood plywood particle board or other composites boards. Why spiral bits are better for plunge cuts. A downcut bit on a cnc. This blog covers the difference between upcut and downcut cnc router bits explaining the situations in which each should be used.