Taper Reamer Angle

Sizes 70 to 30 will only need 1 size drill.

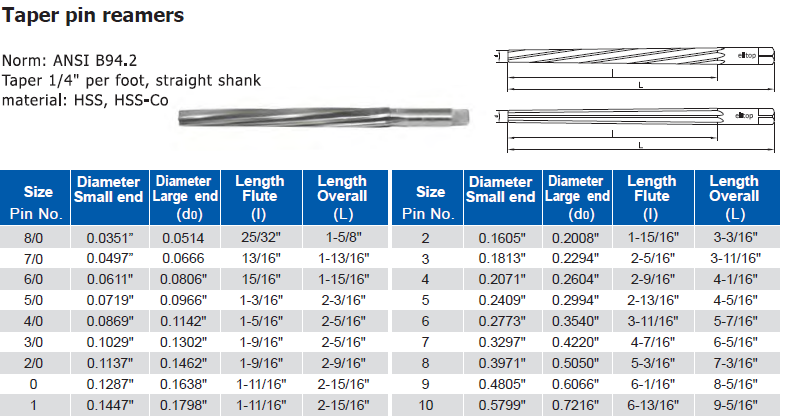

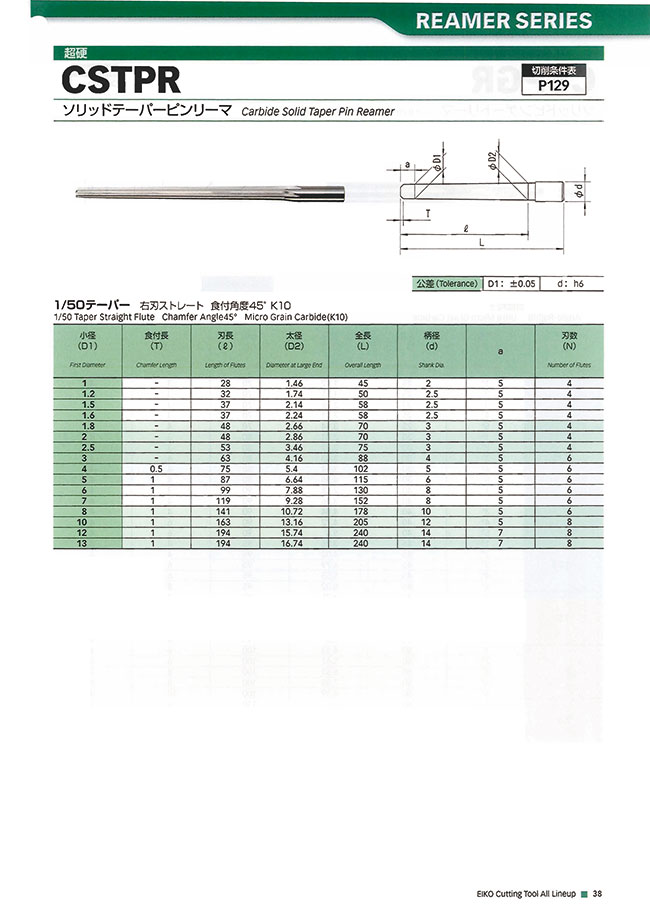

Taper reamer angle. In stock and ready to ship. We have some stock available. To find the number and sizes of drills to be used to step drill holes prior to reaming taper pin hole to fit standard taper pins use the chart on page 1 to to find the length of pin to be used and follow the taper pin length dot to the drill diameter size to use. Reset all here are the main used angles and tapers.

A taper pin is a self tightening device due to the shallow angle of the taper. They may be driven into the tapered hole such that removal can only be done with a hammer and punchthey are sized by a number sequence for example a no4 reamer would use no4 taper pins. The addition of a cylindrical land design creates a smooth cutting tool that can handle the needs of the automotive industry. Plus tapered reamers can improve the surface finish for a polished look.

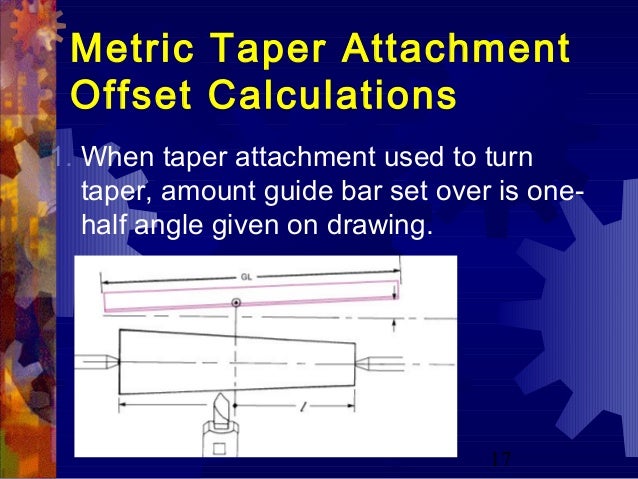

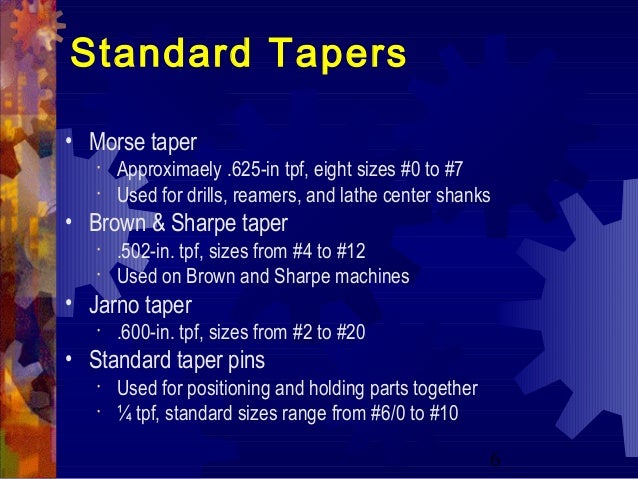

Fill in below three of the parameters from your borehole then the remain parameter will be automaticaly calculated. Taper degree is the central angle of the taper measured in degrees. It can be calculated from the taper or it can be calculated with the number of the different type of tapers. Hss angle reamer with taper shank.

Choose from our selection of taper reamers including inch size hand reamers inch size round shank reamers and more. Use this online calculator to find the taper angle. For reaming 50 60 80 90 100 taper inclusive. A precision tapered reamer is used to make a tapered hole to later receive a tapered pin.

Features benefits we designed our conical automotive tapers with a left hand spiral and right hand cut to get the most out of the high speed steel and create a superior surface finish. For instance a 2 morse taper has an angle of 286133 degrees. L d o. Automotive taper reamer end mills.

A taper reamer can finish any hole after the initial drilling to provide the accurate dimensions required for the job.