Taper Jig Plans Pdf

A side benefit to the adjustable features of the jig is that it allows you to tackle other tough cuts like safely ripping a straight edge on rough edged lumber.

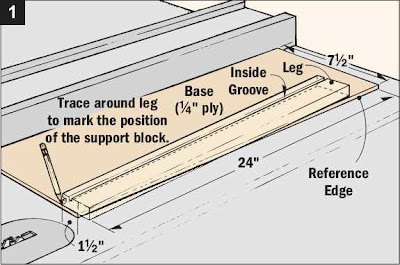

Taper jig plans pdf. Start the saw and feed the jig along the fence to rip the taper. Hold the jig against the rip fence and adjust the fence so the edge of the jig is flush with the inside edges of the blade teeth. Then clamp the leg in position. Making a table saw taper jig.

7 tablesaw taper sled by runnerduck. How to build a taper jig accessory follow along this article and build a taper jig for your table saw. 13 table saw taper jig. This jig can be adjusted to cut two and four sided tapers in almost any size leg.

I have one that i made several years ago that ive used for various projects stair railing rebuild for exampleits an improvement on the classic design in that the body of it is wide enough to let the stay slip over it. This jig offers a permanent and flexible solution. 14 combination taper jig and straight edge. On a square leg blank cut to length mark the ends of the taper on a face and the bottom top.

11 table saw jig works as taper jig 12 true cut taper jig. 9 table saw taper jig. Many fine furniture projects call for tapered legs. 8 taper jig mathematics for true diyers.

D the jig ensures a clean cut lay the blank on the jig aligning the taper marks with the edge of the jig clos est to the blade photos a and b. There are many versions of the tapering jig. 6 taper jig designed by charles neil pdf. Lock the fence and pull the jig back so its clear of the blade.

While there are many methods that could be applied to create this classic design the easiest way may be using a tapering jig for your table sawa tapering jig allows you to adjust your tapered cuts to nearly any angle up to 15 degrees and gives you the ability to do so consistently. Cutting tapers at the table saw usually involves making a quick one use jig. Allows you to taper two adjoining sides of the workpiece by rotating the piece for the second cut. Keep your hands behind the jig support throughout the cut.

Using the marks you just made place the leg on the jig platform so the offcut overhangs the jig and the top of the leg is at the leading end above. Make the nontapered end of the workpiece flush with the trailing end of the jig photo c. I personally cut an 8 inch strip for the base and a 2 inch strip for the fence. Add stop blocks and hold downs.

10 build a tapering jig.