Spindle Runout Measurement

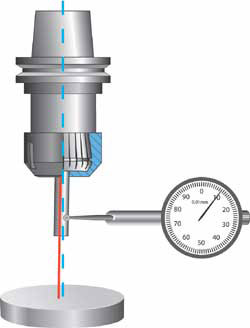

Measuring spindle runout with a dial test indicator one of the leading causes of bit breakage on cnc routers is excessive runout or eccentricity at the cutting tool called tir total indicated runout as recently reported in the trade press excessive runout can have a significant effect on the life of carbide tools.

Spindle runout measurement. Contact mtis experienced application engineers for solutions to your difficult measurement needs. Yes the total indicator runout readings on opposite sides is essentially zero. The motor and spindle assembly is typically loaded with an inertial mass to simu late actual running loads. The probe with its.

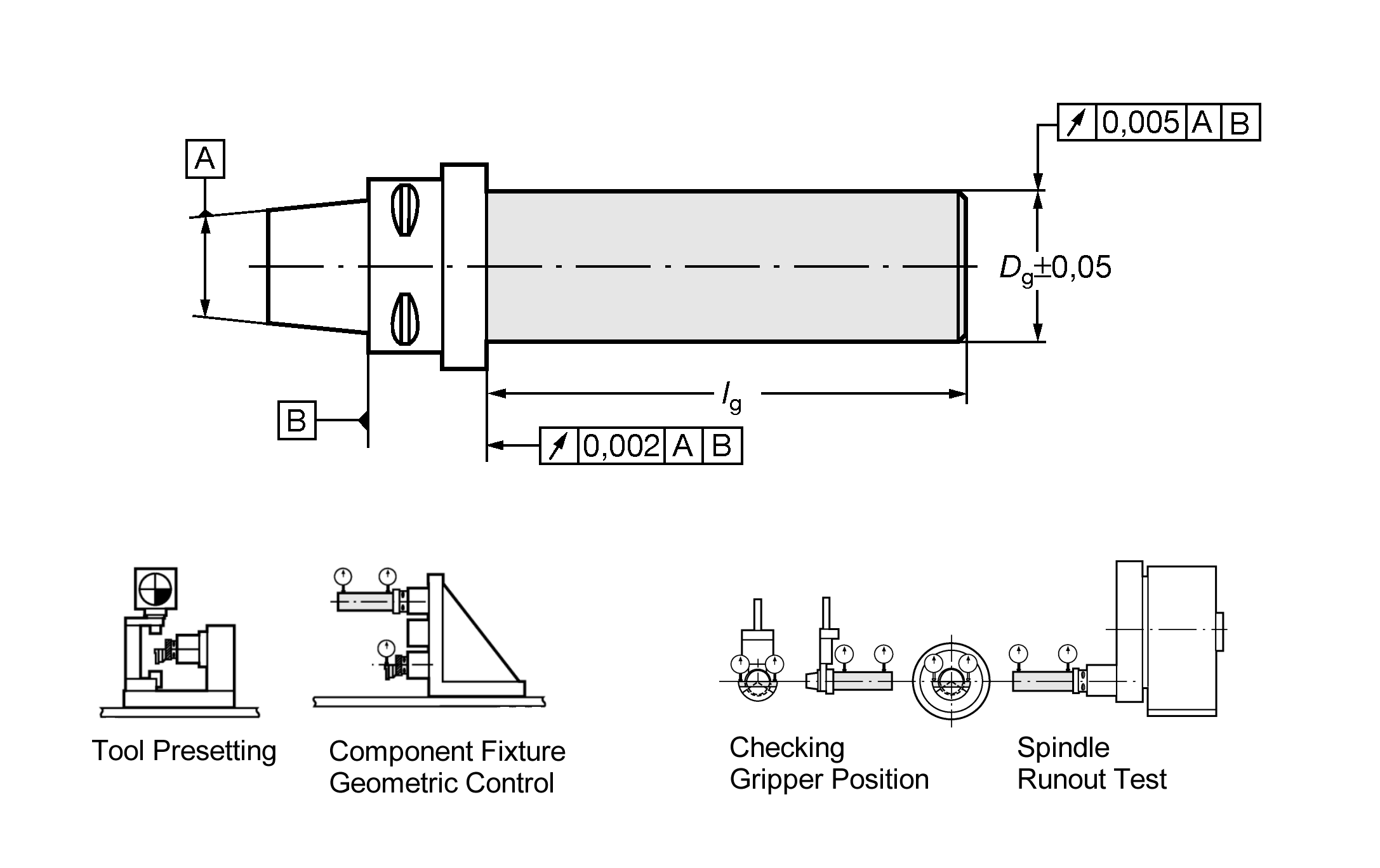

Real time control of spindle runout eddy current probe radial runout master ball upper bearing set lower bearing set fig. How to measure spindle runout. The indicator runout readings do not correspond to spindle angle i think one of the rollers might be worn or something and as it rolls it might be causing the jitter. Given a dial test indicator and a magnetic holder its not hard to measure spindle runout for a tool in the spindle.

A dial indicator is an analog gauge that be used to measure cnc spindle runout. Radial runout of a spindle measured with a master ball reference. Cnc spindle runout measurement dial indicator. This interference can misalign the tool and cause it to rotate off center to the main axis.

For the working machinist it is perhaps more important to define run out as simply a measurement of the spindle runout of a tool or workpiece installed in the cnc machines spindle directly. The runout in this example is measured by placing a proximity probe close to the hub at the end of the spindle. Using dial indicators to measure and understand runout of the mini lathe spindle. A proper load is often required for the spindle servo to maintain a constant speed.

The bearings do feel a little rougher than i would expect when rotating by hand. Radial runout remains constant along the main axis. The resolution obtained was better than 05 microns at a measurement range of 15 mm.