Single Blade Box Joint

After trying several different pins i finally found a 764 drill bit that worked great.

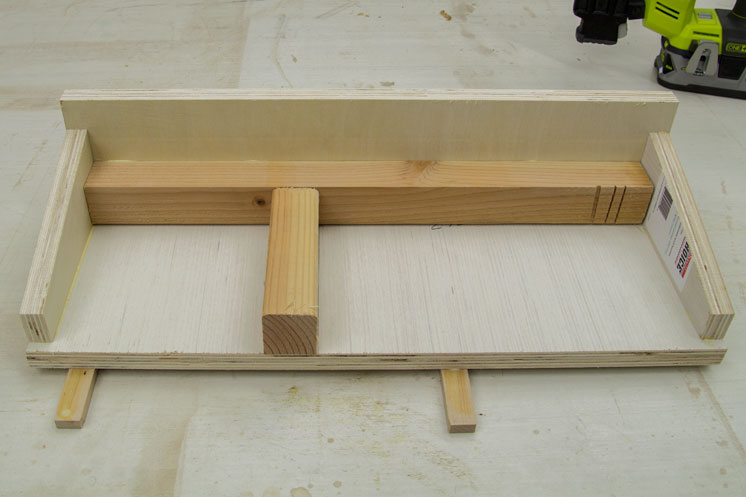

Single blade box joint. My build of a single blade box finger joint jig by. The results are great perfect. It fit snug into a saw kerf but ended up producing too lose of a joint. Plus it looks great on your projects.

Box joints are a strong sturdy and attractive alternative to dovetail jointswhile a through dovetail joint is stronger than a box joint its also more complicated to create. I previously touched on this technique in this article but i thought id cover it again in more detail. For this joint im using a 48 tooth gear which im meshing with the 12 tooth secondary gear on the threaded rod. Lowering the blade to make your joint flush creates a problem.

One of my favourite methods is making 14 box joints or finger joints without using a dado blade. Mario cappellano thewoodfather. Single blade box joint jig plans february 4 2015 thewoodfather projects 52 i was really happy with the way the first version of this jig turned out so when it was time to rebuild it in a more accurate and efficient way i decided to film the process too. Here you can see a how the jig will work with a single blade.

Super simple single blade box finger joint jig. In this set of free woodworking plans learn how to. There are a lot of terrific adjustable jigs you can buy or build that will allow you to create box joints of all different sizes and if you plan on making a lot of projects with box joints a dedicated machine makes sense. This finish nail was the first thing i tried.

It leaves the slot in your jigs fence too tall so it wont fully support the back of the workpiece. They are hard to come by in australia so i decided to make an accurate single blade jig for my table saw. However as youll see in the following steps a perfectly fitting clean box joint is easy to create very quickly with a simple box joint jig for your table saw. When you cut the slots the blade is likely to blow out the unsupported wood.

I love this simple woodworking jig for table saw because with this finger joint jig and a single blade i can cut any finger and socket size in the table saw. The key is finding a pin that is the exact width of your table saw blade. Single blade box joint jig. I can simply swap the block positioning around to create joints twice as wide or cut new ones to make them different sized but still accurate.

There are no complications to make. And as a bonus this method will make it easy to knock together a different design of box joint in the future.

.jpg)