Silver Solder Melting Point Chart

As i stated earlier in understanding your materials you must always be sure that the solder you are using flows at a lower temperature than the materials you are joining.

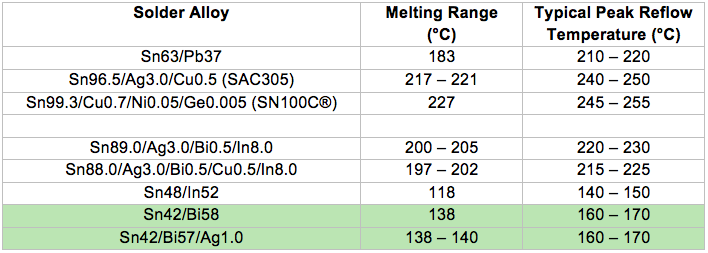

Silver solder melting point chart. Melting range 0c. In the chart below you will find the melt and flow points. Silver solder melting point. Solder that is composed of 56 percent silver will have a melting point of 1145 degrees fahrenheit while solder composed of 80 percent silver melts at 1370 degrees fahrenheit.

Silver brazing frequently called hard soldering or silver soldering is a low temperature brazing process with rods having melting points ranging from 1145 to 1650of 618 to 899oc. What is the melting point of silver solder. Other solder alloys are also available. These characterisitcs mean it is the easiest to use for the model engineer less heat reduces discolouration metal distortion etc.

Kester solder alloys alloy. Solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c degrees f 0 100 327 621 2 98 316 322 601 611 5 95 301 314 574 597 10 90 268 302 514 576 15 85 225 290 437 554 20 80 183. Produces small neat fillets and high strength leak free joints. This temperature chart shows the different solders that are available and their melting temperatures.

Commonly specified solder alloys are shown in the table. Lowest melting point general purpose alloy a free flowing silver solder with excellent capillary properities. The alloys listed may be available in forms other than those indicated. The melting point of silver solder varies depending on the chemical composition of the solder being used.

Silver solder melting point chart. Bar chart of the consumed copper thickness of the solders on a copper ubm after aging for 500 hours and 1000 hours at 150. Solder s o l d er s l d er or in north america s d er is a fusible metal alloy used to create a permanent bond between metal workpieces. Im trying to solder gold wire onto a silver ring shank jewelry.

A typical solder such as 6040 with 60 tin and 40 lead has a melting point approximately between 183 0c to 188 0c. The selection of alloy is determined by application melting temperature and physical properties. Suitable for copperbrassmild steelstainless steel. Alloy temperature chart.

Divided into lead based and lead free types it is a useful reference for engineers and buyers. Solder is melted in order to adhere to and connect the pieces together after cooling which requires that an alloy suitable for use as solder have a lower melting point than the pieces being joined.