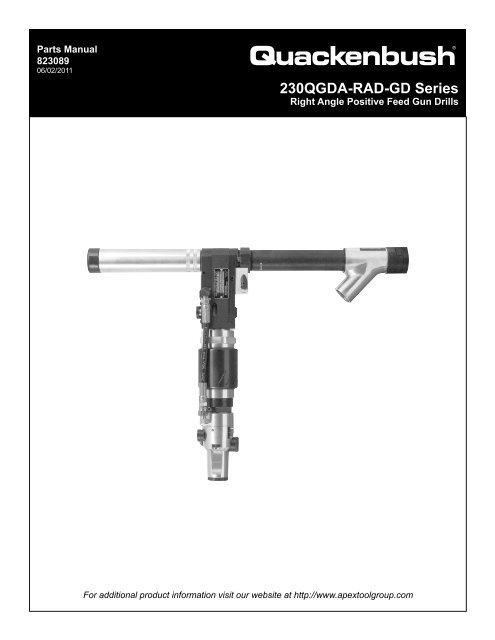

Quackenbush Drill Motor

Adaptive positive feed drill.

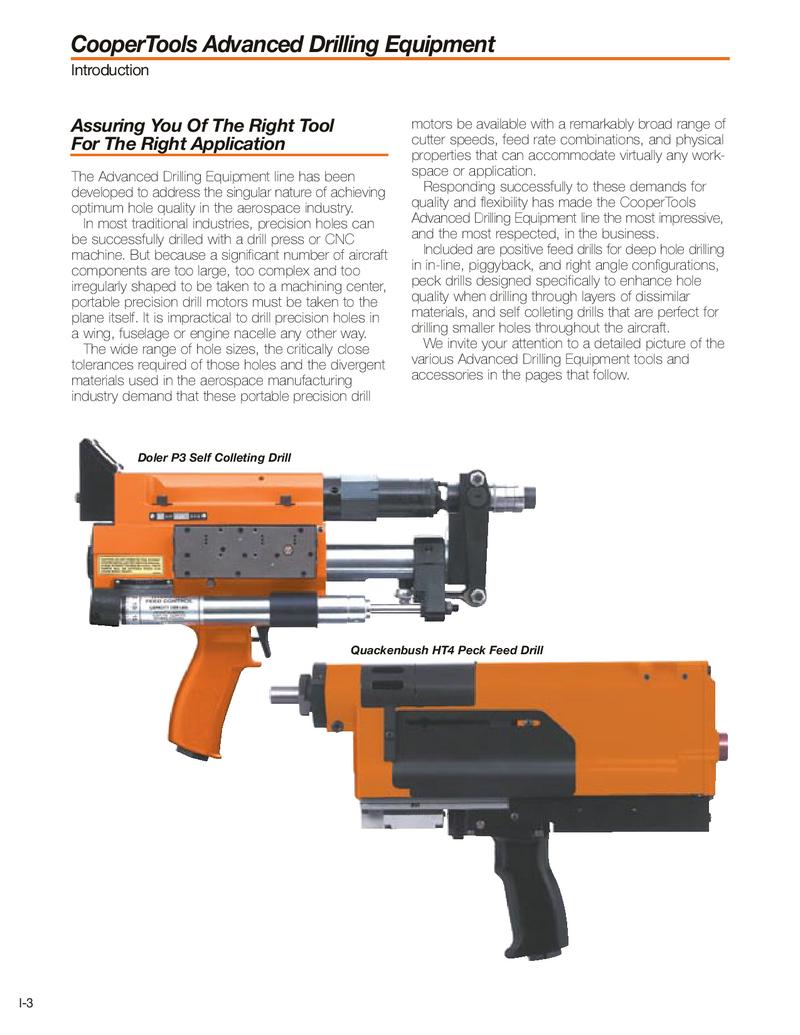

Quackenbush drill motor. Quackenbush self colleting machines 136sc b 118 q matic self colleting drill motor drill capacity. Page 2 quackenbush drills are designed to operate on 90psig 62 bar hoses must be organized and care maximum air pressure using the proper size hose. 5 127mm feed stroke. A2 drilling through a composite honeycomb composite aluminum stack on a 737 engine cowling.

5625 143mm m motor clamp and retract mechanism are air operated. Quackenbush drills are able to shift between high and low drill speeds in less than one second providing enhanced productivity. 158qra series drill pdf manual download. View and download quackenbush 158qra series service manual online.

11875 302mm clamp stroke. Cooper tools introduces the quackenbush adaptive drilling system an advanced drilling system for the aerospace industry that automatically controls drill speeds to match specific materials. Options m vacuum on nose and concentric collet m concentric collet m pneumatic counter m electronic back counter m micro pump m handle on the upper side rated tool performance at 90 psig measured at tool inlet with motor running. Page 3 safety recommendations due to the number and variety of the following recommendations will help reduce or moderate the warning tooling applications the users meth effects of repetitive work motions.

Page 10 pl92 5000en quackenbush 05142012 motor module b 642011pt motor module page 10. If you want a quackenbush drill for your aerospace operation in kansas city wichita dallas fort worth or another city in the midwest then you need to turn to wm. 25 64mm countersink capacity. M easily adaptable to quackenbush 12 22 od thread spindle.

Feed rate is controlled by metering hydraulic fluid through adjustable. Excessive air taken to avoid tripping.