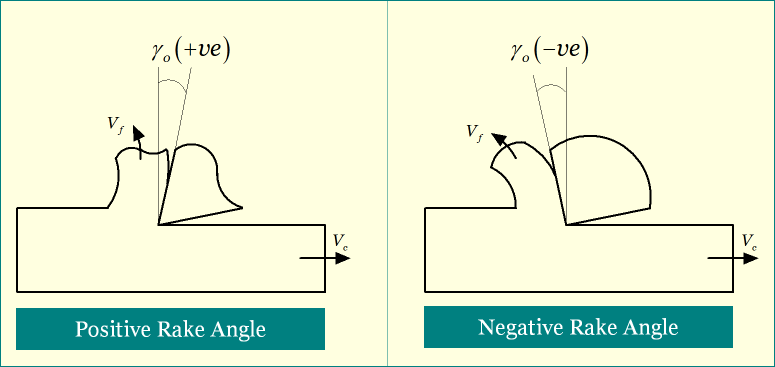

Positive Rake Angle File

Rake angle is a parameter used in various cutting and machining processes describing the angle of the cutting face relative to the work.

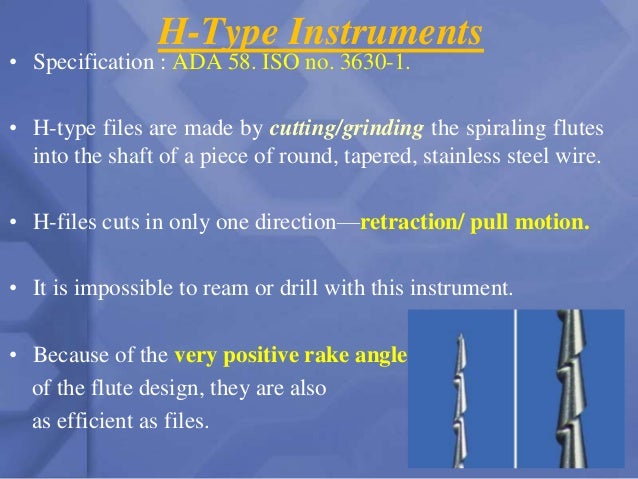

Positive rake angle file. A hook angle can be thought of as the angle at which the tip enters the material. Proper selection of rake angle enhances the overall efficiency and economy of cutting operation. Cons are weak tool tip short life etc. It cannot be negative or zero.

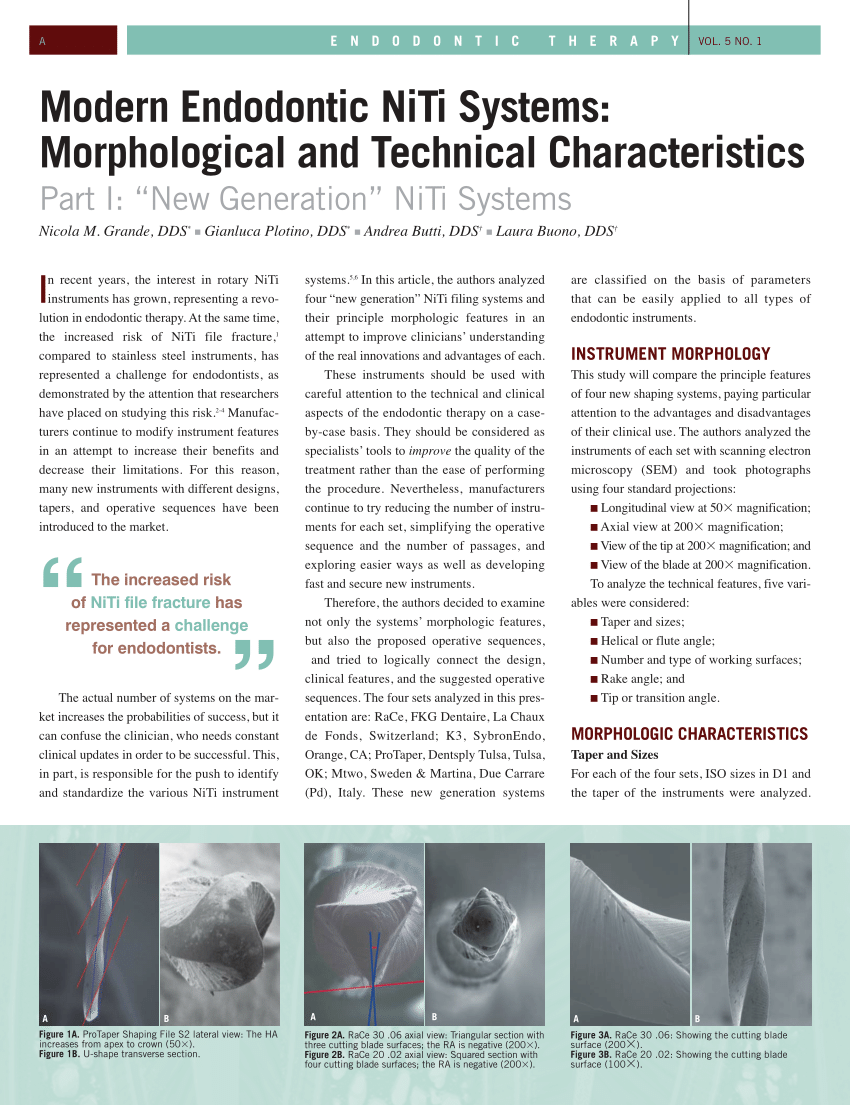

Inclination of flank surface of the cutter is indicated by clearance angle. Inclination of rake surface of the cutter is indicated by rake angle. In some instances as with some quantec files a file may have a blade with a negative rake angle and a positive cutting angle. Rake angle is one of the significant elements in tool geometry.

Recommended rake angles can vary depending on the material being cut tool material depth of cut cutting speed machine and setup. Difference between positive rake and negative rake pintu 05062019 machining rake angle of the cutting tool is defined as the angle of orientation of tools rake surface from the reference plane p r and measured on some other plane. Are positive or negative rake saw blades best. There are three types of rake angles namely positive negative and neutral rake angle.

Definition of rake angle it is the angle of orientation of tools rake surface from the reference plane pr and measured on some other plane. The recommended rake angle depends on tool material material to be cut speed and depth of cutting. Pros are reduced shear strain low cutting power consumption low cutting force lower cutting temperature favorable for continuous chip production lower tool life. Rake angle clearance angle.

A zero rake angle is the easiest to manufacture but has a larger crater wear when compared to positive rake angle as the chip slides over the rake face. The rake or hook angle is the amount of forward or backward lean each tooth has. Positive zero or neutral and negative. Clearance angle must have a positive value.

If the flutes of the file are symmetrical the. If the saw tip enters the material at an angle it will be more efficient than if it slaps down flat. Ability of a file and is obtained by measuring the angle formed by the cutting leading edge and the radius when the file is sectioned perpendicular to the cutting edge. Rake angle can be negative zero or positive.

A tool has a positive rake when the face of the cutting tool slopes away from the cutting edge at inner side. Its various names based on the plane on which it is measured effects and functions typical values and positive negative and zero rake angle are discussed here. There are three types of rake angles.