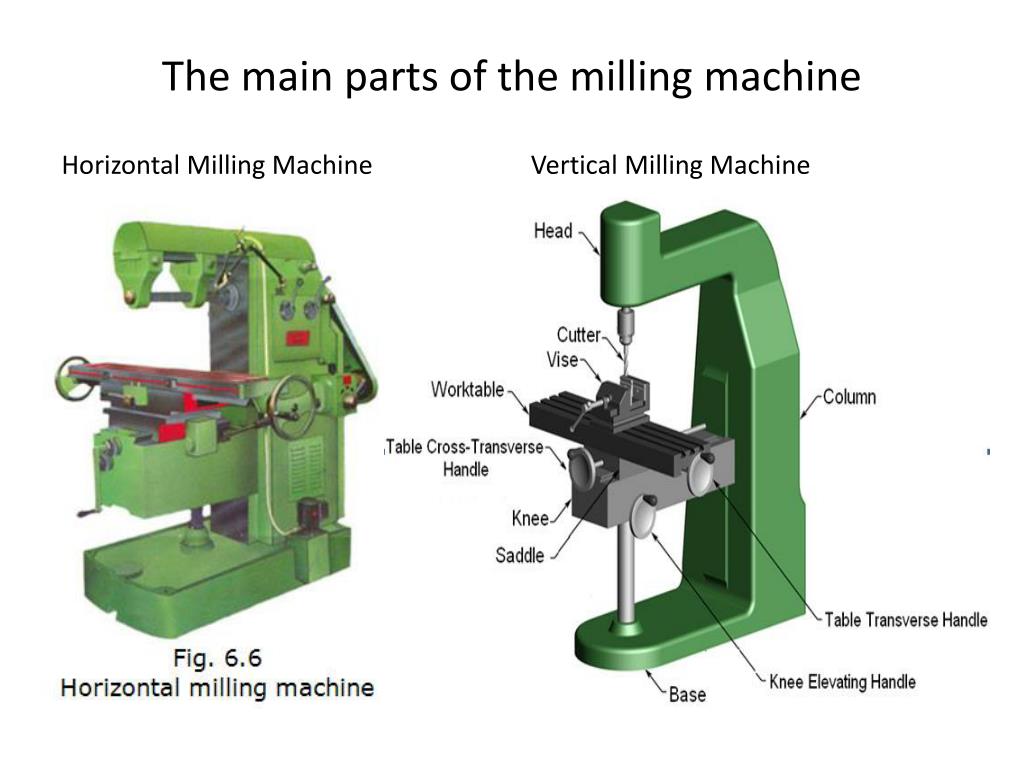

Parts Of A Horizontal Milling Machine

The horizontal milling machine is a kind of machine tool with 12 speeds.

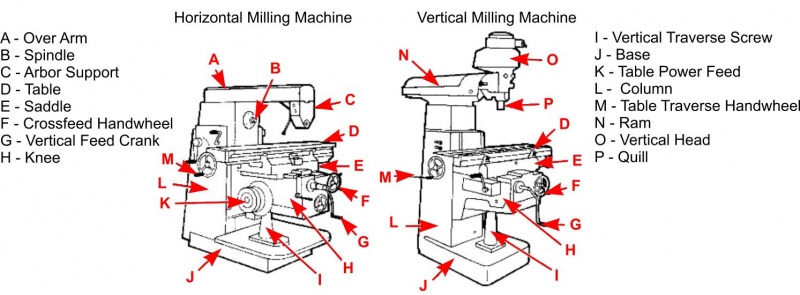

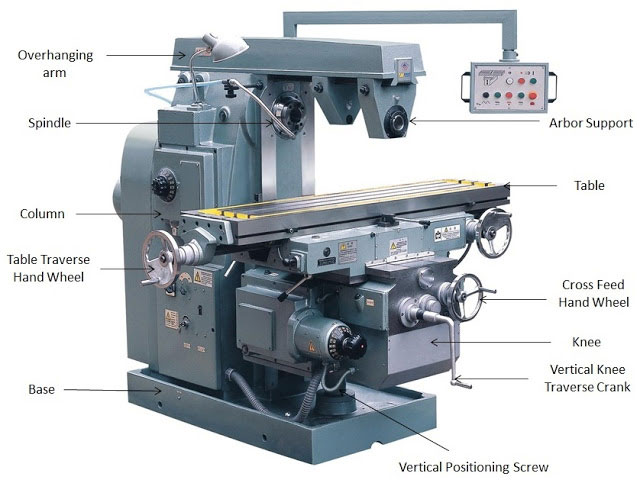

Parts of a horizontal milling machine. The milling is a process of metal removing by feeding the workpiece passes through. Size of milling machine. In horizontal milling machine the axis of rotation of the spindle is horizontal to the table. Milling covers a wide variety of different operations and machines on scales from small individual parts to large heavy duty gang milling operations.

It can be used to process various planes bevels grooves etc. The cutting tool fix in that slot. Riggs explains the parts and functions of the vertical milling machine. It is motor driven and drives the tool.

Learn and grow 55617 views. But it is designed for threaded mounting holes or key slots where a fixture or base is mounted called a tombstone. In turret mills spindle is in stationary position and table is moved in such a way that it will always perpendicular and parallel to the axis of spindle during cutting operation. The milling machine is defined as perhaps most widely used in manufacturing industries after the lathe machine.

This may be done varying direction on one or several axes cutter head speed and pressure. Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. Spindle is the main part of the machine which hold tool at right place in vertical milling machine and hold arbor in horizontal milling machine. It is a moving part which is in rotary motion.

Horizontal machines also have a fourth axis tombstone capacity. Most of the milling machine classified above has self electric driven motor coolant systems power operated table feed and variable spindle speeds. With various cylindrical milling cutters wafer milling cutters angle milling cutters forming milling cutters and end milling cutters. Hindimilling machine parts or components of milling machine.

It has a slot on the front end of it. The below image shows the typical size of a horizontal knee type milling machine. However in the case of lathe machine tool the tools used there single point cutting tools but in the case of this machine the tool used is multi point cutting tools. When you buy a horizontal milling machine the spindle is pointing horizontally and the table is horizontal.

The size of the milling machine is determined by the dimensions of its maximum length of longitudinal cross and vertical travel of the table and also by working surface of the machine.