Panel Glue Up Rack

To make the rack youll need two 12 floor flanges two 2 x 12 pipe nipples two 12 900 elbows a 36 x 12 pipe and as many 34 tees as you like.

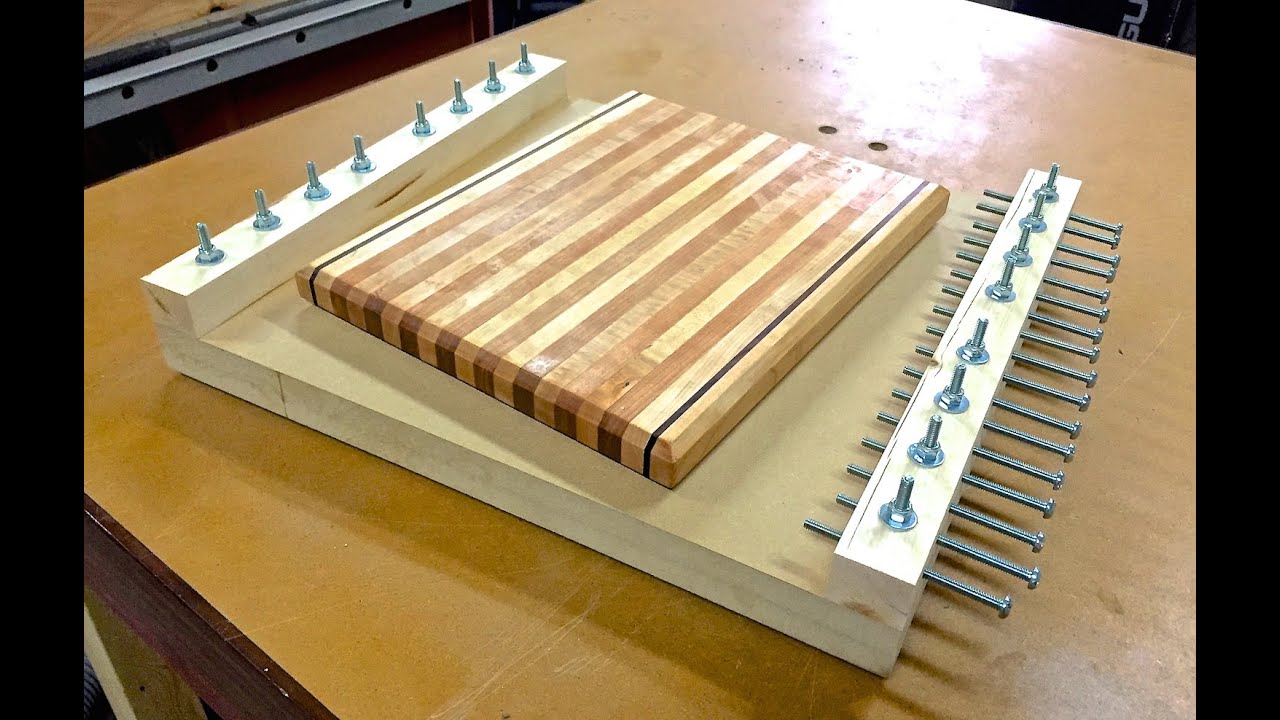

Panel glue up rack. The goal is a quick and easy glue up of joined and. The three pony clamps with pipe cost about 2500 each the six deep reach clamps 2600 each on the low end for a total of 23100 not to mention the cost in materials and labor for the cauls. I mounted this towel bar style rack on my shop wall for the times when i need to clamp up a small panel. It can handle up to a 15 thick 4ft x8ft glue up.

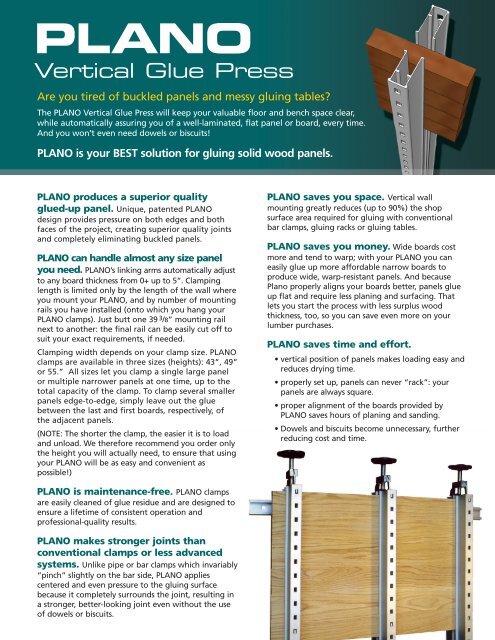

A few useful techniques and one not so good. The jlt panel clamp and pneumatic panel flattener saved my life. It is designed to size edge glued panels safely and accurately. Conquer one of the challenges of wide flat panel construction with a proven routine that makes glue up glitch free and a lot faster.

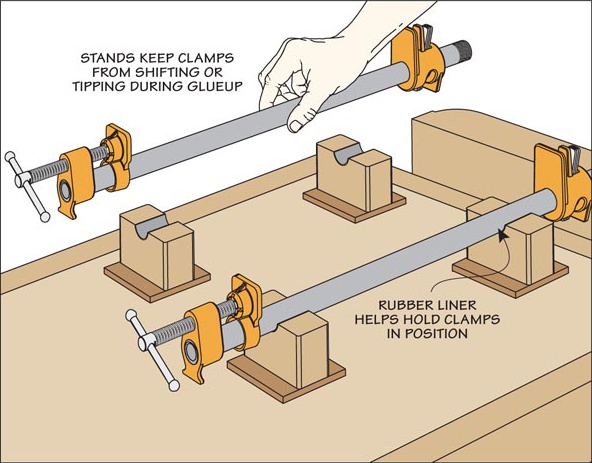

Glue press large glue rack clamp rack glue large flat table tops glue multiple panels at a time and on and on and on. Spread glue along one edge of the first board and slide it into place between the platens and press bars. Open the pipe clamps about 1 wider than the width of the overall glue up. Pull the press bars far enough out on the bolts so boards will slide in easily.

They posted a pdf of the cutting diagram as. Your edge to edge glue up should be 1 2 wider than what is required for the finished panel. It takes up very little shop space. Heres how to put your new panel press to work.

Construction begins on the glue up station. Quick machinery company value leader in gluing equipment clamp racks clamp carriers pod presses conveyorized glue applicators and roller coater glue spreaders. For many beginning woodworkers one of the most intimidating aspects of solid wood furniture construction is gluing up wide flat panels for tabletops. Regarding my comment on the use of cauls for panel glue up lets analyze the rube goldberg assembly shown in the above photos of a relatively small panel.

Rest it on the clamp tail stops. If you want to use a 12 wide board it may seem counter intuitive but what you need to do is cut it down the middle and then incorporate the two narrower pieces in the glue up. The 2s is a multi axis mulit function cnc horizonal machine. This raised panel door machine can also be pillar linked to any order entry program and scan bar codes to virtually eliminate the need for the operator to do anything other than load the part to be cut.

This is my first working prototype for a wall mounted large panel glue up station for my shop. Not really but it does add for a catchy opening.