Motor Rpm Calculation Pdf

Per hp at 575 volts a 3 phase motor draws 1 amp per hp at 460 volts a 3 phase motor draws 125 amp per hp at 230 volts a 3 phase motor draws 25 amp per hp at 230 volts a single phase motor draws 5 amp per hp.

Motor rpm calculation pdf. The formulas and calculations which appear below should be used for estimating purposes only. The product of the motor current and the applied voltage is the power input to the motor. At each point selected for calculation the efficiency h of the motor is the mechanical power output divided by the electrical power input. The electrician makes the following measurements.

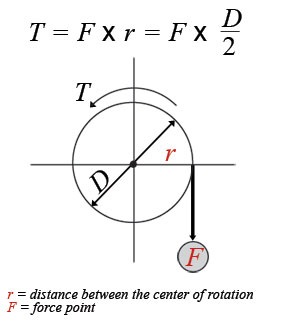

The salesman may wish to check the customers specified values with the formulas in this section however if there is serious doubt. Formula for calculating stepping motor speed. In our example input electrical power of the motor is 022 a x 6 v 132 w output mechanical power is 1000 rpm x 2 x 314 x 000126 nm 60 0132 w. At 1800 rpm a motor develops a 3 lbft.

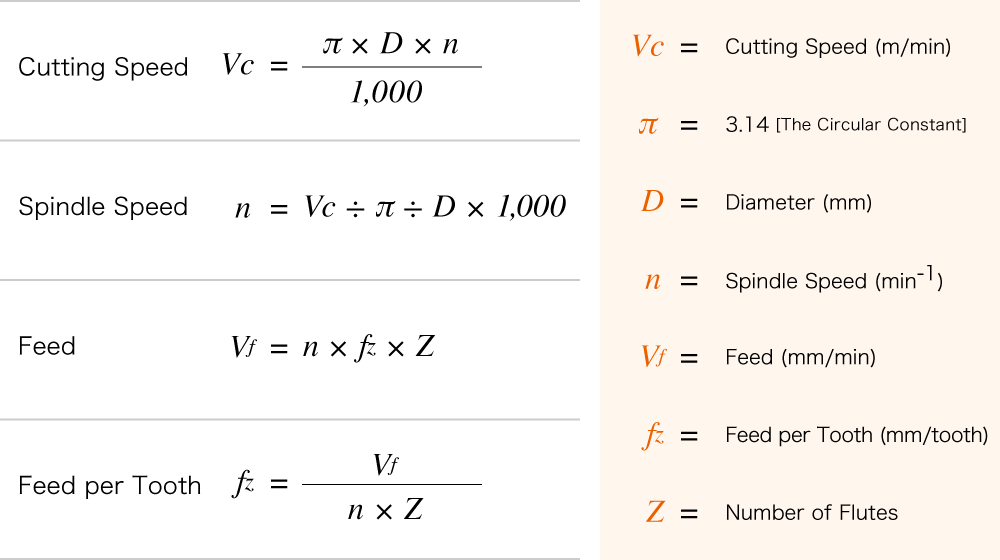

Drive step resolution is set for 1000 steps per revolution. Input power calculation an existing motor is identified as a 40 hp 1800 rpm unit with an open drip proof enclosure. Gpm x psi x 3677 rpm torque in inch pounds this company assumes no liability for errors in data nor in safe andor satisfactory operation of equipment designed from this information. The voltage applied to the motor is given and the current at various levels of torque has been plottedthe product of the motor current and the applied voltage is the power input to the motor.

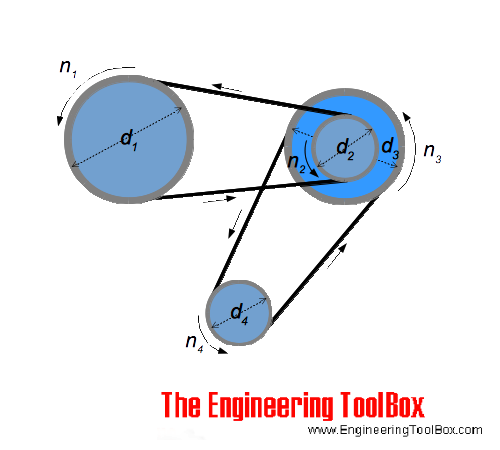

To the motor is given and the current at various levels of torque has been plotted. The smaller pulley will always wear the fastest as it is turning more revolutions per minute and it has a smaller circumference for the belt to spread the wear over. At no load you have maximum speed and zero torque. Per hp at 1200 rpm a motor develops a 45 lbft.

V ab 467v i a 36 amps. The motor pulley is less costly it is the easy one to change and as the smaller of the two pulleys it probably has the greatest wear on it. It is the responsibility of the customer to specify the required motor hp torque and accelerating time for his application. At each point selected for calculation the efficiency of the motor is the mechanical power output divided by the electrical power input.

First off if you need a variable frequency drive for your ac motor make sure you check out our web store. Rpm 120 frequency of poles in the motor. Motor torque changes with the speed. Below is the rpm formula for steppering motor drives that use pulse signals to create motion.

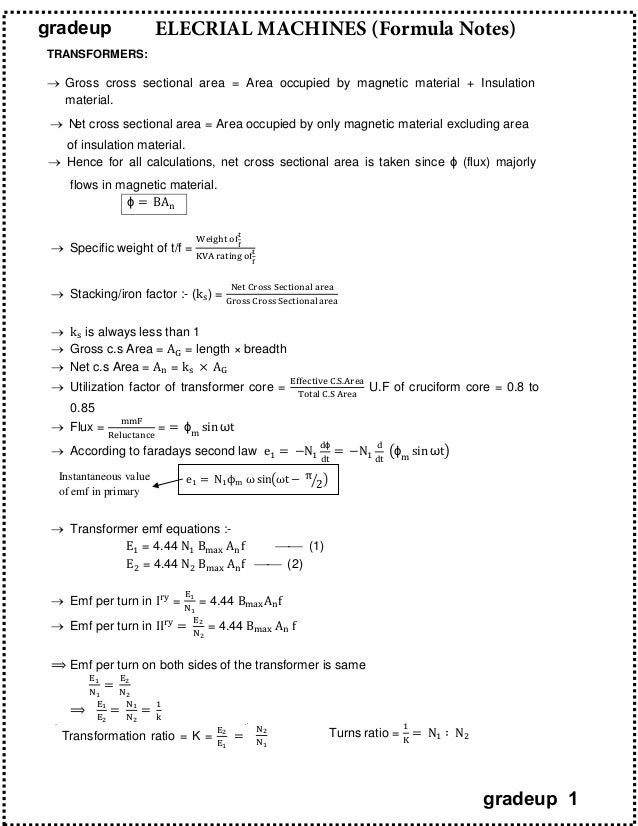

Once again a sample. Basic motor formulas and calculations. A step angle fz pulse frequency in hertz example 1. Calculating rpm for a three phase induction motor is relatively simple acthree phase induction motorrpmis determined by the formula.

How much torque does a motor develop at 1200 psi 1500 rpm with 10 gpm input.