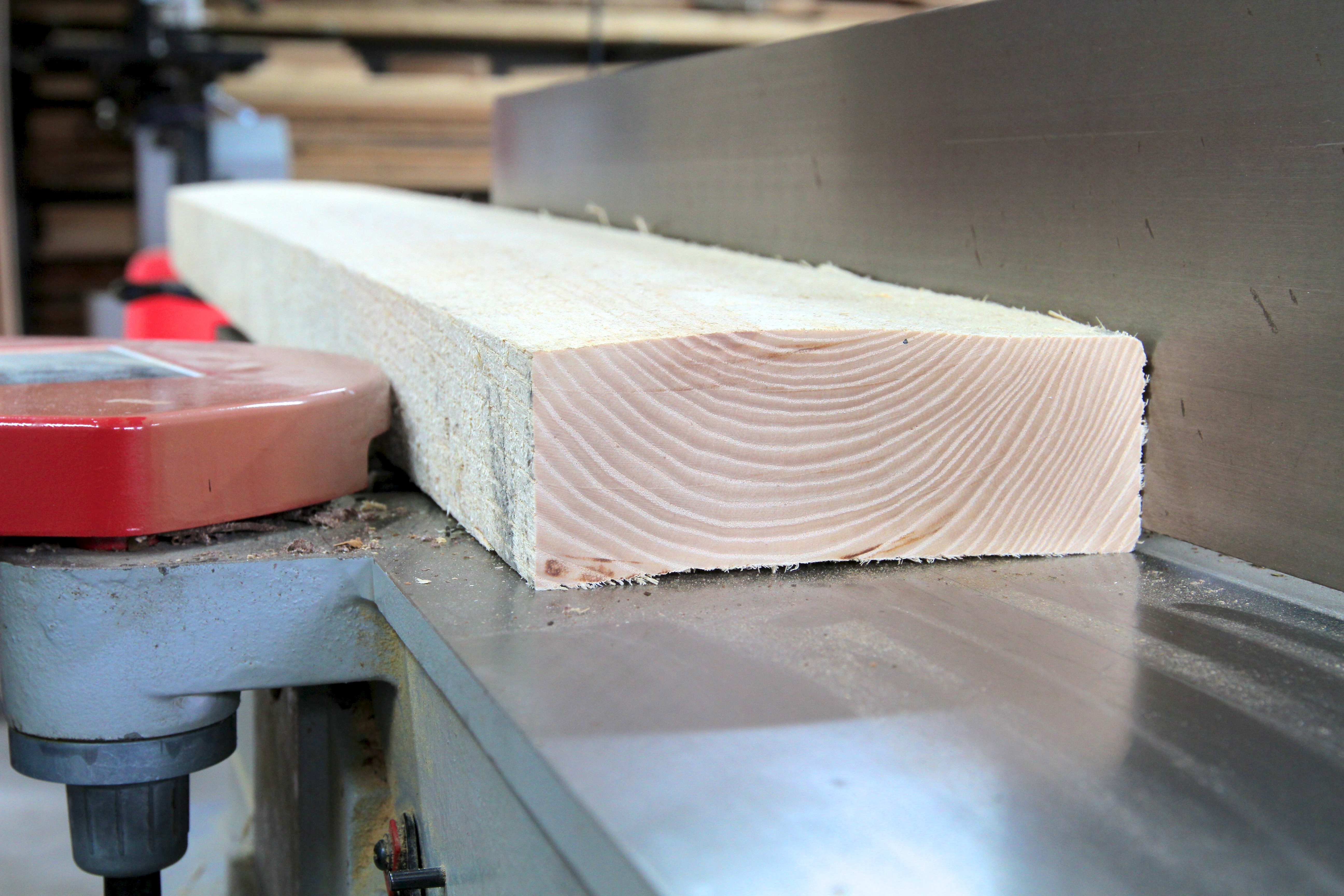

Milling Rough Lumber

Its better to cut a big rough sawn board into individual pieces one for each part on your cutting list more or less and then start milling.

Milling rough lumber. Please note that in order to fully understand the milling process you must take wood theory prior to this workshop. Roughcut hemlock larch lumber mill oran milling llc. Learn the basics of milling and the tools needed there or loads of ways to mill your own wood but in this video i will cover the process that i use to prepare my lumber to become furniture. In addition i construct rough cut custom timber and lumber projects.

Check out this video for a detailed explanation on how lumber is cut and sold including how to speak like a pro at the lumberyard and how to calculate a board foot. Picking out and hauling home rough sawn lumber and then milling it into usable boards is time consuming so buy extra. To get back into the swing of things i wanted to share a more comprehensive video on how i mill rough lumber to. Its better to cut a big roughsawn board into individual pieces one for each part on your cutting list more or less and then start milling.

Surface 4 sides. And rough sawn lumber can be milled to custom thickness giving you more flexibility with your woodworking designs. When i see milling rough lumber what i would expect is an article on how to mill logs into rough lumber. Milling black walnut for.

High quality local idaho red fir and pine is used. You dont want to go through the whole process to mill one board to replace one that gets damaged. You might think the best strategy for milling rough lumber is to flatten as large a piece as possible then cut it into smaller parts. See our services and options below for your special projects and give us a call or email us for more information.

Rough sawn lumber is typically less expensive than pre surfaced lumber. However this article is about starting with rough sawn lumber to create finished sizes. You might think that the best strategy for milling rough lumber is to flatten as large a piece as possible then cut it into smaller parts.