Lathe Tool Bit Grinding Jig

Grinding lathe tool bits is a bit of an art.

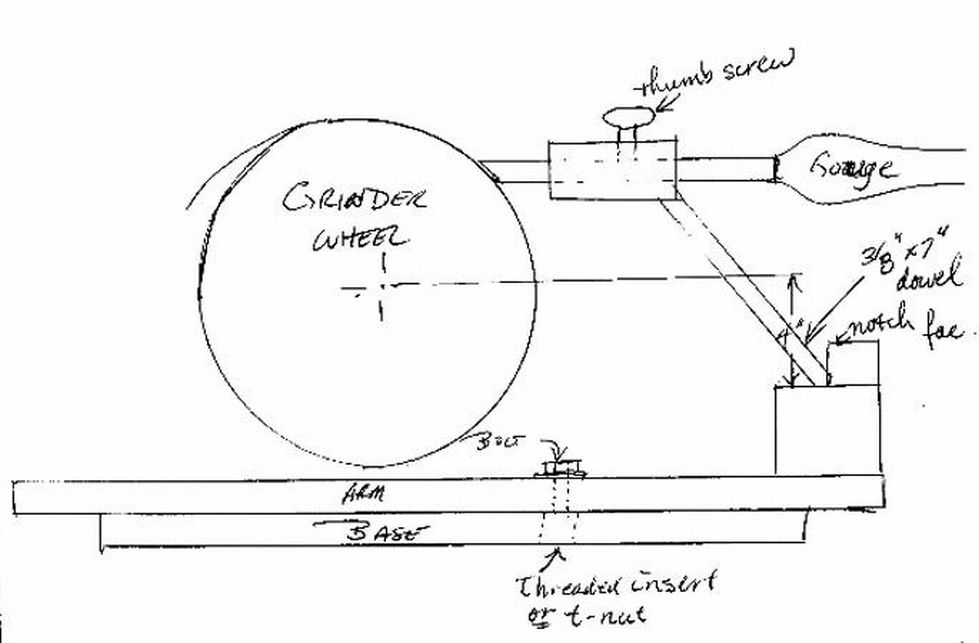

Lathe tool bit grinding jig. The relief angle of 80 below the cutting edges is set by angling the grinder table so when the bit is on the grinding jig the top edge of the bit touches at the 80 tangent point. There really is no substitute for sharp tools especially on small low powered equipment where we want to minimize cutting forces. This foray into tool grinding theory was educational but the resulting bits cut too well. It takes some practice to get good at it.

You need to create a cutting edge that is sharp extends out so that the cutting edge and not the side of the tool. Grinding tool bits when you purchase a new lathe tool bit it might have an angle on the end but it is not properly sharpened for turning. Grinding jig gj 01 this tool from alisam engineering is a reproduction of south bend lathe works cutter bit grinding block not in production for many years. I dont have one surface grinder so my fixture is useless to me.

For me it has been a bit of a challenge to consistently get lathe tool relief angles right and i have not always sharpened them as soon as i should have. Each grinding block will come with your choice of two 2 square tool bit holders for 8499. The little jig shown in the header photo was constructed for grinding threading tools. In this video i show how to grind a hss ar cutter for the lathe using a home made tool grinder with a diamond wheel or cbn grinding wheel.

Here is a small handy grinding jig that is easy to use. Woodcut tools tru grind turning tool sharpener is an easy repeatable precise jig and base for lathe woodturning tools 46 out of 5 stars 45 10995 109. The first tool i made as an apprentice back in 1972 was a fixture to hold 38 lathe bits for grinding a threading tool but it needs a surface grinder to do the grinding. Set your grinder tool rest at 10 15 degrees.

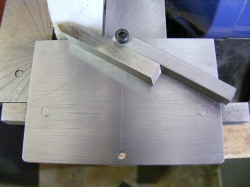

Taig lathe lathe tool sharpening jig. A home made cutter for the mini lathe.