Lag Screw Pilot Hole

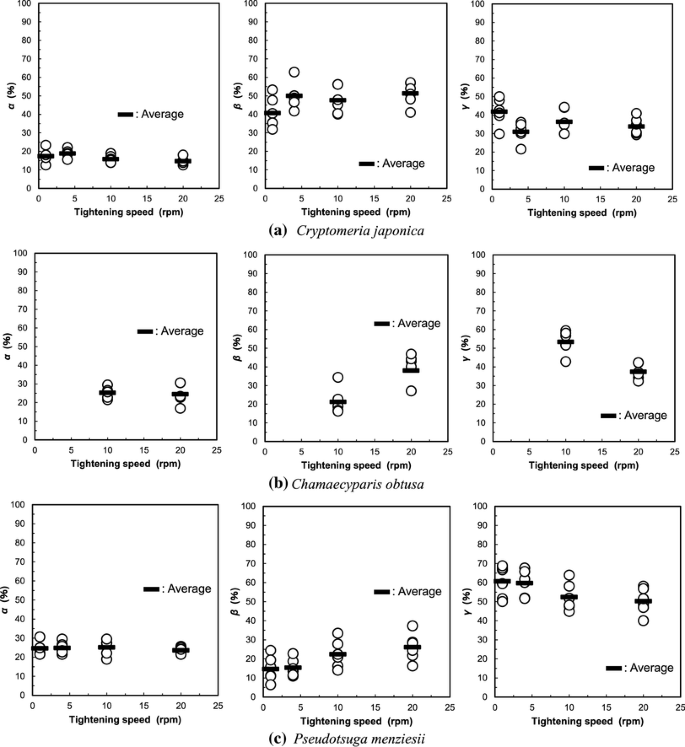

Refer to the chart below for commonly accepted hole sizes.

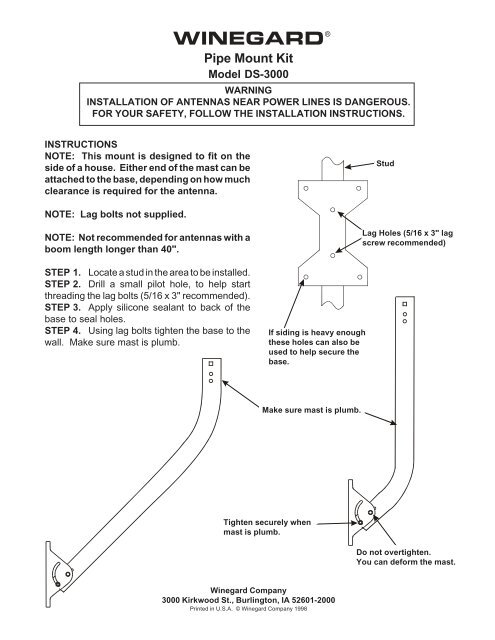

Lag screw pilot hole. The pilot hole for the body the unthreaded section of the shank adjacent to the head should match the bolt size 38 hole for a 38 bolt for example. Typical pilot hole. Ing the design and installation of standard lag screws. Pilot hole size can range as follows.

In order to do this you first drill a hole with a bit that matches the outer diameter of the screws threads countersinking or counterboring where appropriate. Hard wood 65 to 85 of the shank diameter for wood with a specific gravity g 06. The pilot hole serves as a guide for the screw to prevent it from going off course or splintering the material it is being installed in. There are a number of variables that may change the required pilot hole dimensions including bolt length diameter and wood species.

Then with the fracture reduced the lag screw is inserted through the plate first as described below. Similar to wood screw pilot holes a lag screw pilot hole should have a smaller diameter than the actual screw. Soft wood 40 to 70 of the shank diameter for wood with g 05. Lag screw pilot hole diameters pilot or lead holes are typically used to ease the installation of large diameter lag bolts.

This hole completely clears the material allowing the screw to pass through without cutting into the wood. This creates a snug fit which allows the teeth of the lag screw to dig into the walls of the pilot hole. Pilot or lead holes are typically used to ease the installation of lag bolts. Table 1 pilot hole sizes for lag bolts some reference books will suggest the use of soap on the end of the threaded portion of the lag bolt in order to provide some lubrication to the threads.

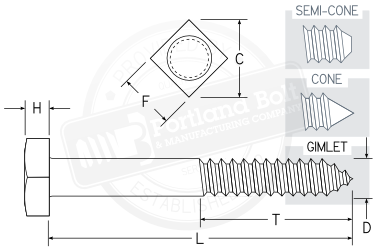

Otherwise youll find that the screw will become overly resistant as it gets deeper into the pilot hole. The remaining screws are then inserted through the plate. If youre working with brass screws go up 1 size as well to accommodate the softer metal. Unless specified the lag bolts we make will have a semi cone point not a gimlet point typically supplied on smaller import product.

A pilot hole is a hole that is drilled into the material you wish to use a lag screw on. Then drill a pilot hole in the bottom piece to accept the screws threads. Medium wood 60 to 75 of the shank diameter for wood with 05 g 06. If the fracture plane necessitates that the lag screw is inserted from a position where it would be awkward to apply a plate the lag screw can be inserted outside the plate.

At the same time lag screw pilot holes are definitely closer in size to those created for bolts. Non tapered screws include drywall screws some appearance wood screws.