How To Make A Knife Bolster

Since the handle is lighter than the blade the bolster contributes to better balance and improves control.

How to make a knife bolster. An excellent way to enhance a knife project with a new type of recessed bolster making it very unusual giving a good grippy feel. The art of making. Once this is done i make about six xerox copies of the drawing that will be cut and pasted to material as needed. It is also one more layer to work with a file andor anodize.

Here are the two pieces after some work on the buffing wheel. Remember that the bolster fronts will be nearly impossible to finish once pinned to the knife. First steps toward a beauty of a bolster because my work is so complicated my first step is to draw and refine everything on paper working out all of the issues in terms of design and proportions. The knife that i decided to make has a full tang the handle has the same profile as the tang with slabs fastened to each side by means of pins screws metal tubing bolts epoxy etc.

How to make bolsters. Make a knife with cheap basic amazon tools. The thickness of a bolster shows how thick the original chunk of steel wasand the thicker the better. Brass bolsters can be used to enhance almost any full tang knife.

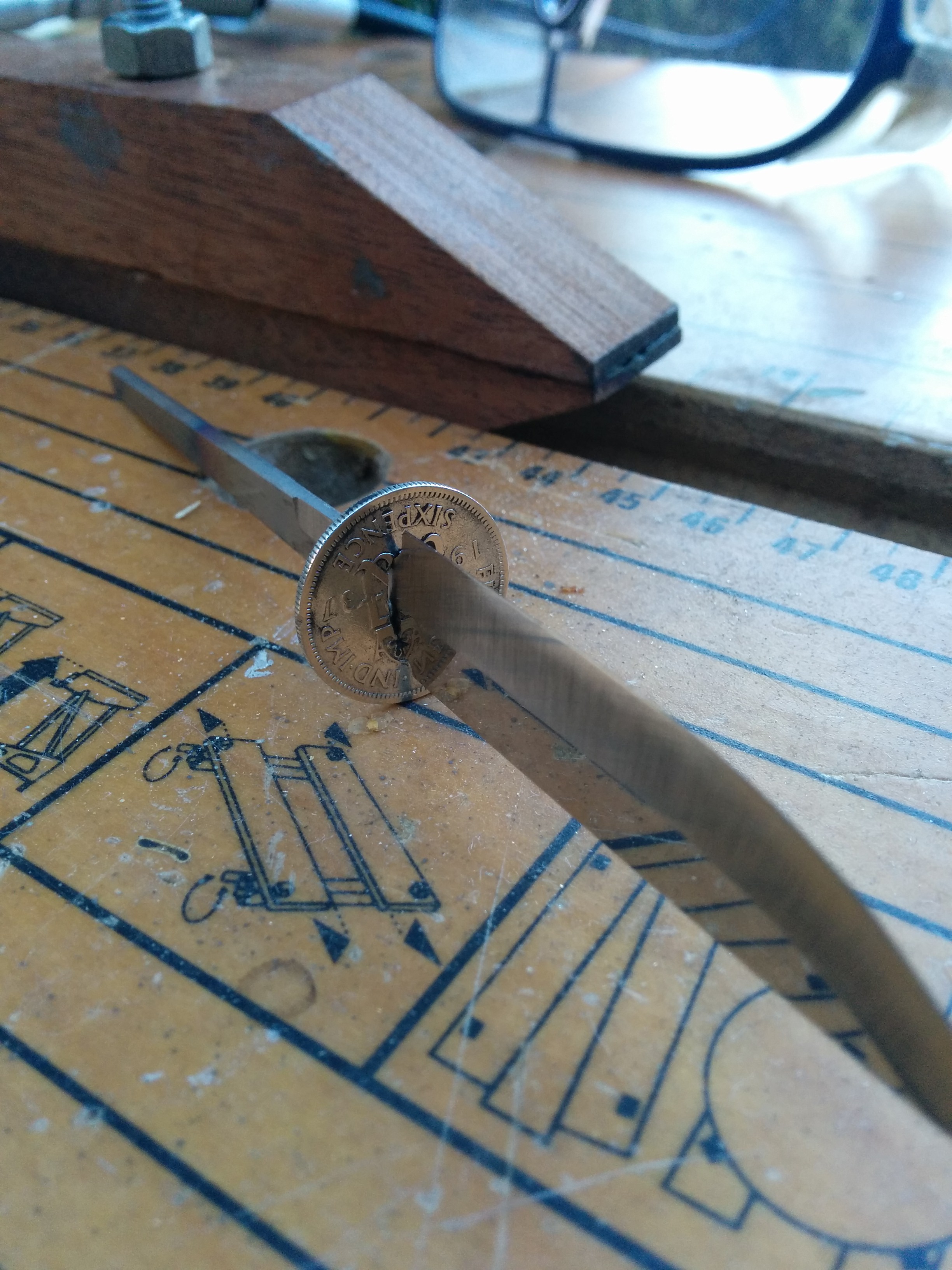

Finishing means shaping sanding and buffing. 10mm x 24mm x 37mm slot. Brass pins on brass bolster pieces. Another layer underneath the bolster will give the knife a dynamic and dimensional appearance.

Knife making how to make and mount brass bolsters. A knife bolster is a thick junction between the handle and the knife blade which provides a smooth transition from the blade to the handle. A bolster strengthens the knife adds durability and provides a counter balance. Bolsters are relatively easy for knife makers to fabricate and mounting them.

A partial tang extends partially from the blade and is completely hidden within the handle body. The additional bolster layer will thicken things up a bit as well as give another visual element to the overall design of the knife. A bolster indicates that a knife has been forged from a single chunk of steel as opposed to being stamped out of a roll of sheet metal.