How To Make A Dovetail Saw

Chisel along your thickness mark to remove the wood between the tails.

How to make a dovetail saw. The dovetail saw aims to prevent both of those issues by providing a hand saw that can make incredibly precise cuts with the rigorous accuracy necessary for flush dovetail joints. That said there are actually a couple of different ways to make dovetail saws and each approach also requires using a different type of cutting technique. We offer a dovetail saw in all of our saw brands. This is also an entry to toolmake16.

I used an old cheap saw and filed all the teeth down and made them myself. Wood frame dovetail saw homemade woodworking tools while i cant say that this is a saw that will get a lot of use in my shop it was interesting to make. Avoid chiseling too much about four or five soft hits should do the trick. Link to website article.

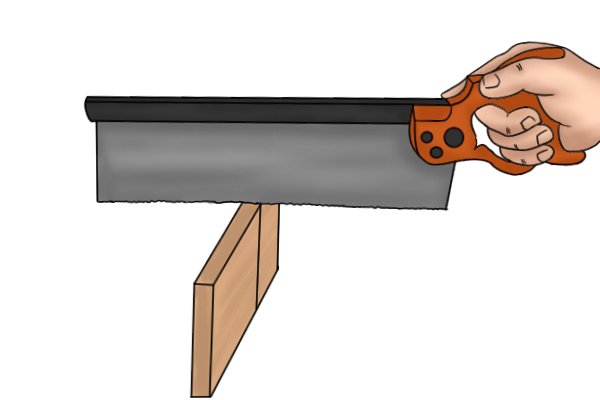

Using your dovetail saw cut across the wood towards the base of the tails on each side. Dont go for it on one shot however. All are available in either rip or crosscut tooth formation with 20 teeth per inch. The iron rule for this setup is to start fat and finish lean.

After the scoring cut adjust the router tables fence to make the dovetail full depth. In this video i make a dovetail saw from scratch. Dovetail joints can be cut by hand as they have been for thousands of years but power tools such as a table saw or a router and jig make the job much faster and accessible for total beginners. Its the traditional joint of choice for joining boards at right angles.

All are re sharpenable and have heavy folded brass backs that offer the perfect blade tension and balance for cutting. Here is how i went about setting out and cutting my dovetails using hand tools and with some practice you can too. Who knows maybe ill throw aside my power tools one day and only use hand tools or maybe i can use this for special projects where its not practical to use a router. There are times when the video is really loud guard your ears.