How To Calculate Rpm From Pulley Size

How to calculate driven pulley dia or rpm.

How to calculate rpm from pulley size. Enter the motor pulley size in inches. The cell plate 45 cell x 0395 rpm 1776 seeds drop in one revolution. Whether you need a pulley for a household clothesline or for your sailboat determining the necessary pulley size requires just a few simple calculations. Pulley and speed calculator.

The first ratio 4422 2 and the second ratio 2822 127. If you know any 3 values pulley sizes or rpm and need to calculate the 4th enter the 3 known values and hit calculate to find the missing value. For example if your small pulley is 80mm diameter and spins at 1000 rpm and you need to find the second pulley size to spin it at 400 rpm enter pulley1 80 pulley 1 rpm 1000 pulley 2 rpm 400 and hit calculate to find the second pulley diameter. Iss video me pulley ka size kaise calculate karte hai according to driven machine exp.

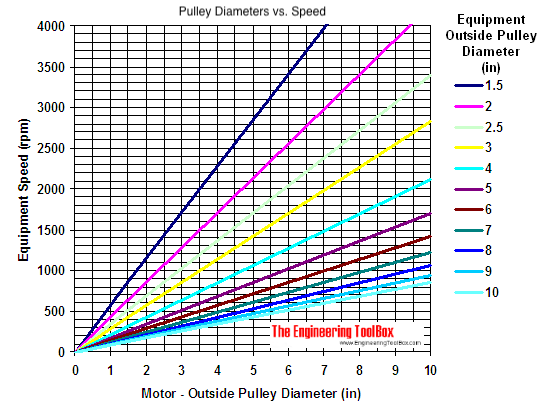

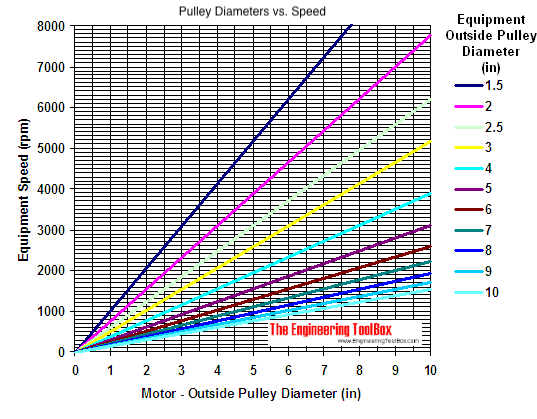

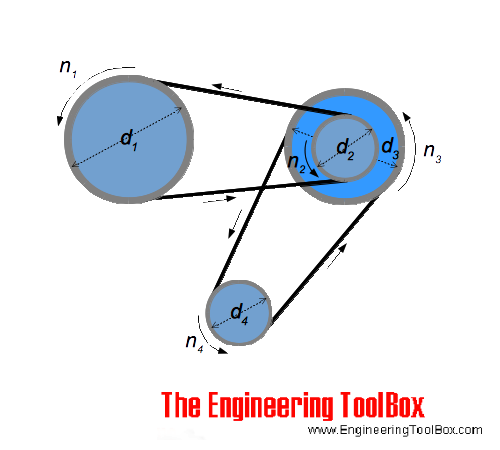

Below is a small calculator that will solve the ratio for you. U rpm. The output of the first stage. More than one stages of pulley speeds can be calculated in a compound drive system.

125 cm 1776 seeds 704 cm. Enter the drive pulley size. To use this calculator you must enter at least 3 values in the spaces below. 2 just for sake of argument 2000 rpm use a 2 driven pulley 11 1000 rpm use a 4 driven pulley 12.

Enter the motor speed in rpms. Motor rpm 2000 rpm motor drive pulley dia. The two basic pulley systems are rope and pulley and belt and pulley which are made of two different sized pulleys. Simply enter the values and click calculate.

Check the circle next to the item you are solving for and enter the remain three items in the spaces provided. Take the stated motor rpm or measured and simply apply the appropriate ratio to the diameter of the motor pulley to get the speed you want. Seed spacing down the row then is. 1750 rpm 1000 rpm 35 inches d 2 d 2 6125 inches.

Calculate the pulley ratio by dividing the pulleys pitch diameter by the pitch diameter of the drive pulley. Enter the driven pulley size in inches. Adjust the drive and driven pulley sizes to achieve a certain rpm output. To make this easier.

Enter the rpm of the drive motor. The driver pulley the smaller and the driven pulley the larger. Using this pulley and belt size calculator. For example suppose the drive shaft has a diameter of 22 inches and two pulleys driven by the belt have diameters of 44 inches and 28 inches.