Half Nut Lever Of Lathe Machine

With the lathe off you might try putting a slight amount of pressure on the thread lever while working the feed lever up and down to see if the half nuts break free.

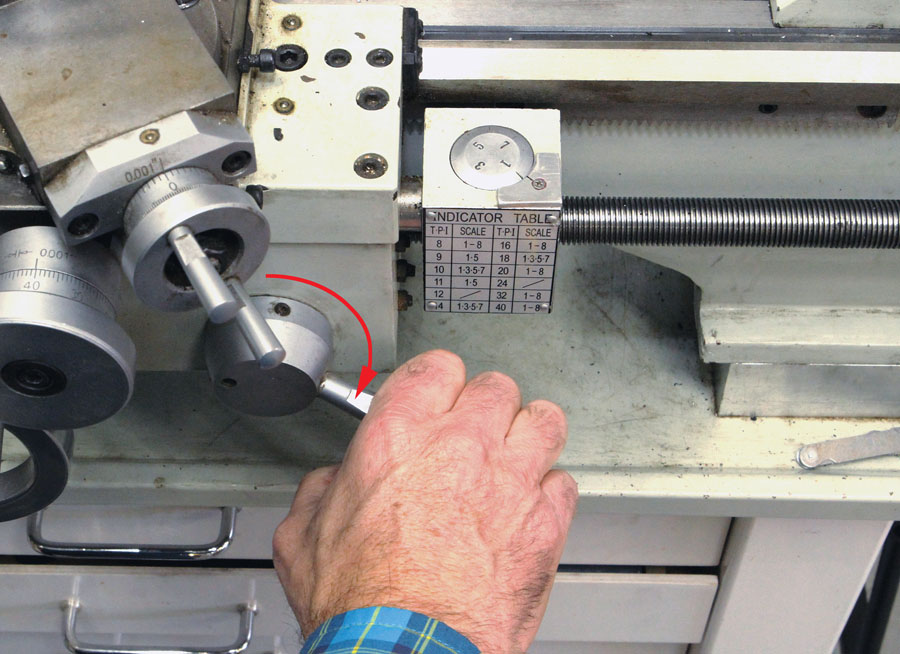

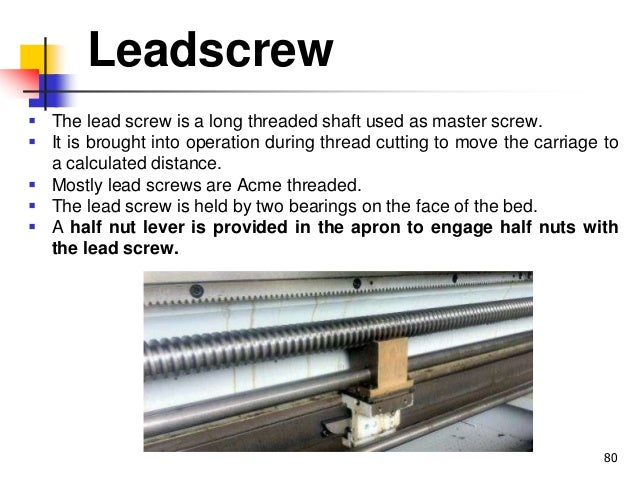

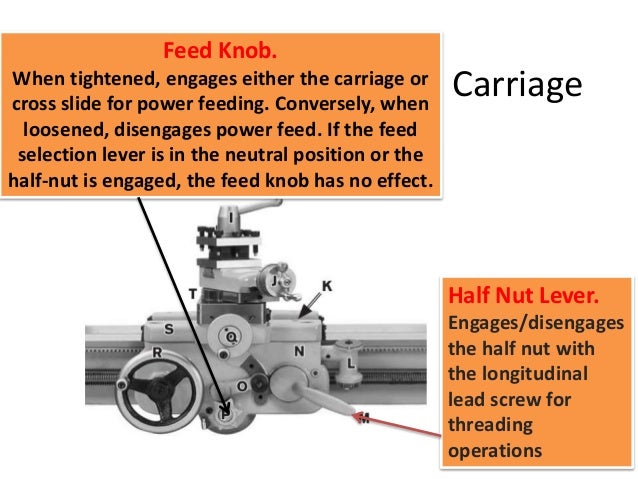

Half nut lever of lathe machine. It has a 30 degree included angle. The dial tells you when to engage the half nut lever so the tool follows the same thread groove every time. When i removed the spring loaded pin that allows engagement of the half nut lever i noticed that it had a strange configuration on the end. The half nut lever closes the clasp nuts onto the leadscrew for threading having changed over the years the names given to various parts of the lathe are still not completely standardised.

The cross slide makes up the x axis of the machine. I downloaded the first three books in the series for. The cross slide allows for tool travel 90 degrees to the bed of the lathe. Half nuts for lathes thang010146.

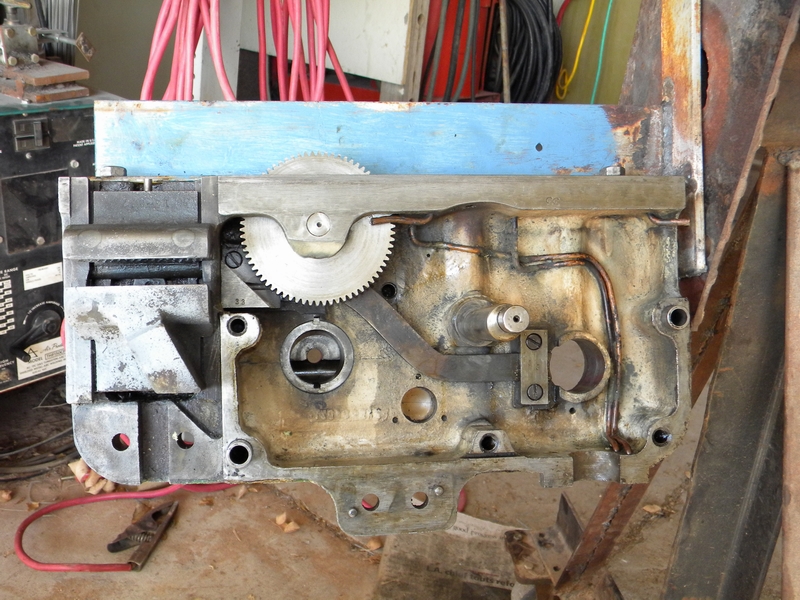

Has anyone noticed this on their 9a lathe during disassemble. This video shows the assembly of the lead screw apron and split nut for the lathe project i am building. I am building a gingery metal lathe. Easy to manufacture compared to square thread.

I repaired a set of half nuts for a lathe of mine an older south bend 10 by setting up the half nuts in the position they occupy when closed bored them out about 18 on a side facing the ends off a similar amount then made a new nut with flanges on the ends to fit snugly in the half nuts split the bushing and secured the halves in the nut casting with a rolpin through each end of the. The feed lever 8 is what interlocks with the thread half nut lever 9. I will attempt to attach a photo. Advantages of trapezoidal thread over square thread 1.

The x axis of the machine controls the diameter of your work. Lathe machine duration. One is about 63 degrees the opposite is about 45 degrees. The feed lever must be in the neutral center position in order to engage the half nuts.

There are two angles on the end of this pin. Stronger at the root. A trapezoidal thread is used in the leadscrew of lathe machine.