Drill Press Maintenance Checklist

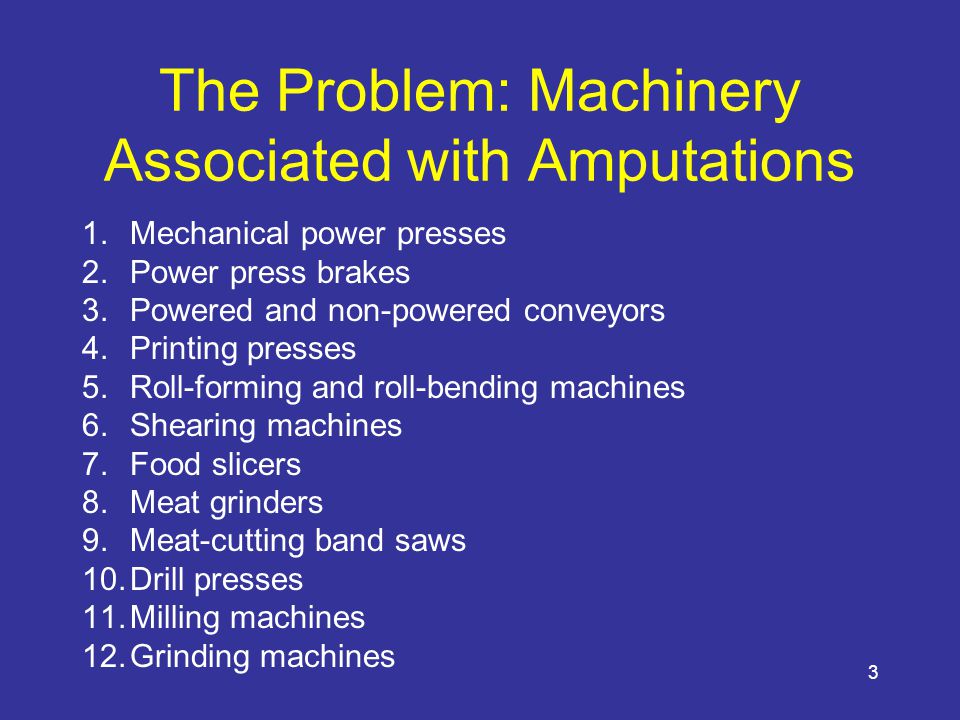

Correct drill speed has been set.

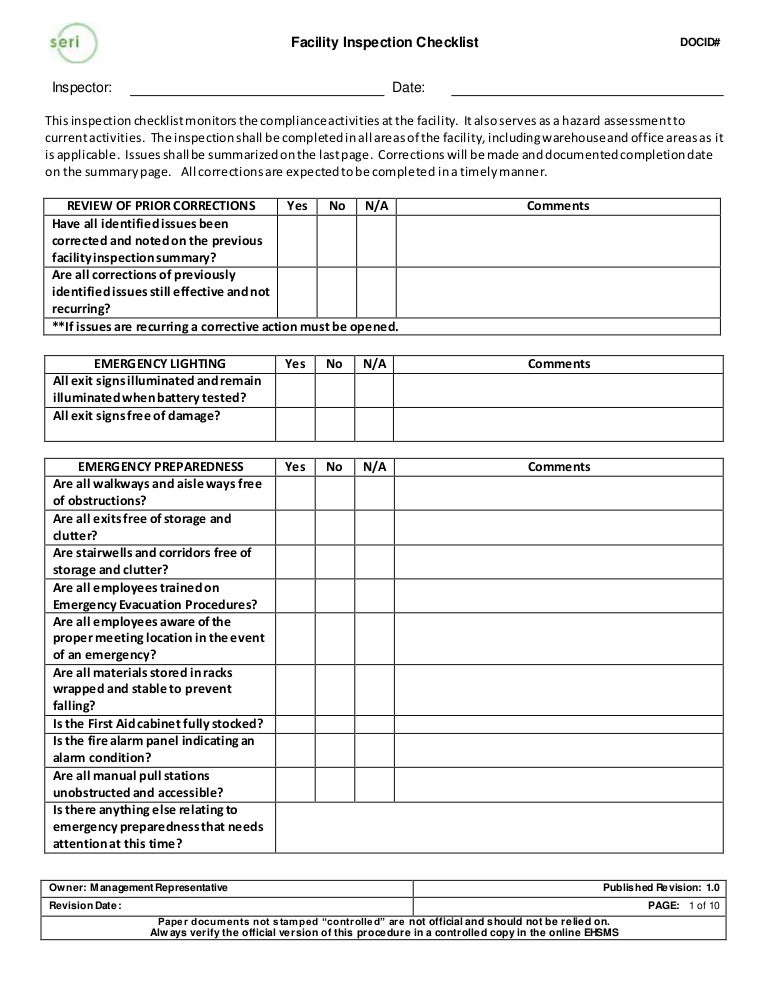

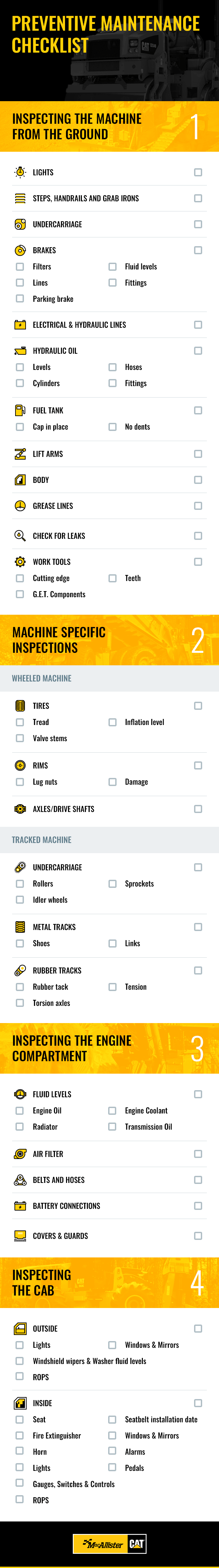

Drill press maintenance checklist. Drill bit is tight in chuck and chuck key has been removed. Drill press check for loose pulley setscrews belt wear clean and oil working parts check chuck jaws inspect plug cord starter. Drill press maintenance tips. A maintenance routine must be developed and sustained to keep it working at its highest performance standards.

Safe work procedure checklist. If removed for maintenance purposes use extreme caution and replace the guards immediately. Preventive maintenance is a small price to pay to keep your press running. A drill press is a pretty simple looking machine.

By sandor nagyszalanczy jun 22 2011. Keep safety guards in place at all times when the machine is in use. Drawings instructions specifications etc is clearly understood. Drill press and drill a hole.

A drill press is a pretty simple looking machine. Though the types would vary in the area of fine points the steps for proper maintenance are similar. Make sure the drill press is firmly secured to the floor or bench before use. Box 886 nashua nh 03060 6349 603 889 4101 ext.

While its relatively maintenance free that doesnt mean that you shouldnt do regular check ups and lubrication of your shops drill press. Modified on 20180916 2142 by jeff joslin categorized as maintenance yearly maintenance. Yearly maintenance checklist print. Work piece is securely clamped.

Replace missing after searching the area and damaged drill bits so the mill and lathe drill sets are complete. Make sure guarding is in place and in good condition. Before further use of the machine a guard or other part that is damaged. It features the fundamental maintenance procedures for seven major woodworking power tools.

The drill press comes in different styles and functions specifically designed for wood metal or plastic. Carl jean is a service manager with greenerd press machine co po. The table saw jointer drill press dust collector air compressor pneumatic nailer and even a.