Drawer Lock Joint

First cut the drawer side joint.

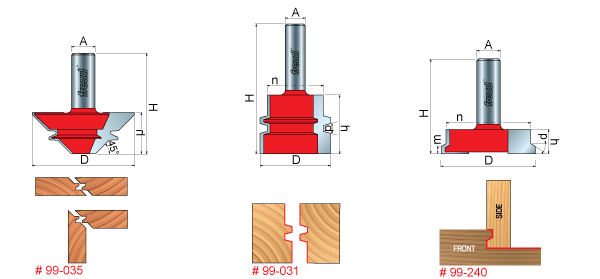

Drawer lock joint. Drawer lock bits this specialty router bit allows you to cut all the corner joints with one router table setup. There are specialized router bits you can use to cut this type of joint on a router table but the technique ill demonstrate here only requires a stack dado and a zero clearance throat plate. Drawer lock joints are easy to assemble and attractive. Although you can build drawer joints using any number of methods we think lock rabbet joints like the ones above make sense for attaching the sides fronts and backs of most drawers.

Although not as strong as a dovetail joint a well made lock rabbet joint will hold up fine unless the drawer takes heavy regular pounding. With minor adjustments the bit will even mill the groove for the bottom. Learn how to make a lock rabbet joint and improve the look and strength when building cabinet drawers. For drawer lock router bits 5552 7852 and the katana drawer lock router bit 18850 the end notch on the side is roughly 316.

A lock joint is a good drawer joint because it holds together tightly as the drawer is moved. Use a 14 dado stack for this project. Set the fence 14 from the blade edge. Set the blade 14 above the table.

The drawer lock joint. Wood magazines jeff mertz shows you this technique in building great cabinet doors and drawers. The interlocking design is strong and offers significant gluing surface. It would be nice to have one dedicated for a dado stack so i dont have to switch blades constantly.

Drawer lock joints made using a drawer lock router bit are a great way to put drawers together. For this project i chose to make my drawers using a small dra. There are many ways to make a drawer. Im not about to say one way is better than another.

Once the setup is right the joint can be cut very fast and the mechanical interlock the joint provides makes it very strong. The downside to this method. As part of that i needed to make several drawers. The locking rabbet drawer joint is a pretty easy method for drawer building if you have a table saw or two.

Then set the bit height so that the end notch on the drawer side about 18 for bit 7851 is the same as the end notch on the bit. I seriously am considering buying a small second table saw.