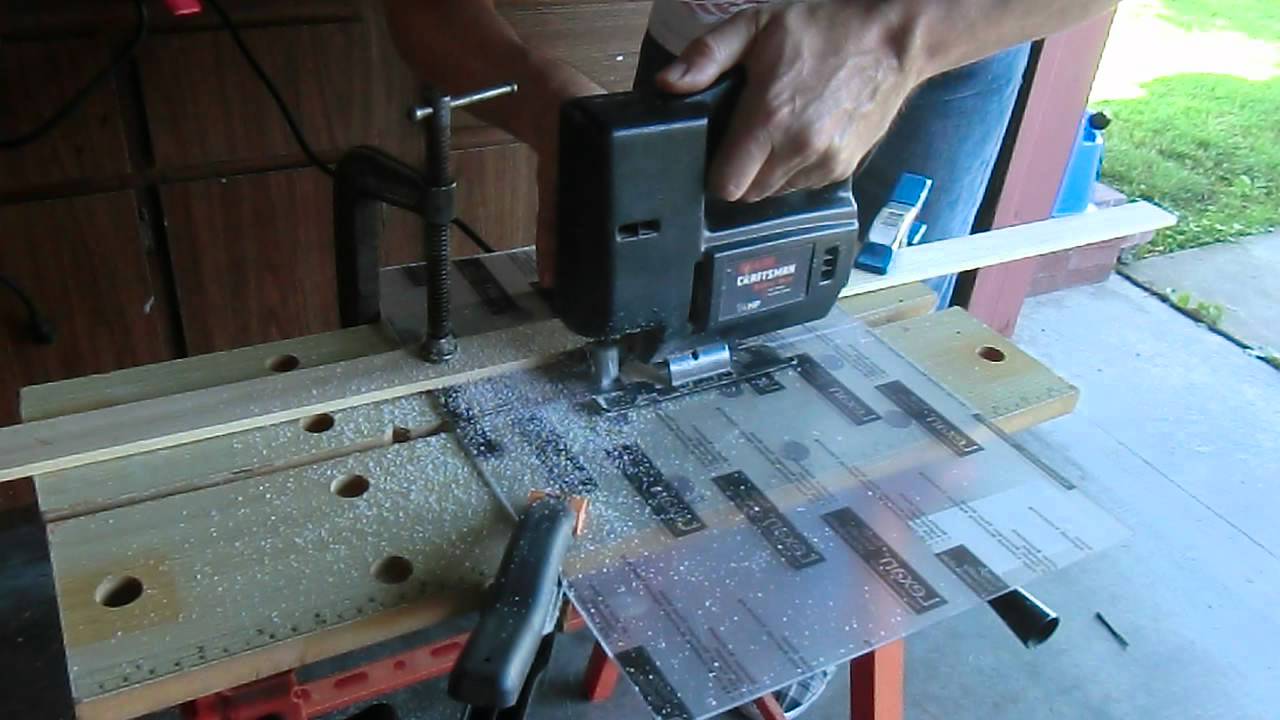

Cutting Lexan Thermoclear

You can cut with tin snips smooth with a plane and sand round corners.

Cutting lexan thermoclear. Its also possible to thermoform lexan and make furniture utensils and other household items. Lexan thermoclear sheet sabics polycarbonate pc multiwall materials called lexan thermoclear sheet portfolio offers a variety of structures colors and finishes. The two sided uv protected surface offers advantages in economical cutting. Wear safety glasses for eye protection and ear protection for noisy power tools.

Cutting 16 mm polycarbonate. When the polycarbonate panels are cut to size small particles may have entered the flute channels. Installation mistakes are minimised since both sheet surfaces may be faced outwards. A saber saw may be useful for cutting holes or rounding corners.

Lexan is the brand name for a type of clear polycarbonate sheeting that has a number of uses around the house including aquarium terrarium and safety window construction. Use a sharp utility knife and straight edge for cutting thin sheets. Bends easy simple curves complex curves even put in metal brake and bend a. Lexan thermoclear multiwall polycarbonate sheeting features a two sided proprietary surface treatment designed to protect the sheet against the degrading effects of ultra violet radiation in natural sunlight.

How to cut multi wall polycarbonate. Lexan thermoclear dripgard sheet offers a specially developed coating on the inner surface that reduces the formation of condensation droplets. Lexan thermoclear multiwall polycarbonate sheeting features a two sided proprietary surface treatment designed to protect the sheet against the degrading effects of ultra violet radiation in natural sunlight. A table saw and circular saw are the best cutting tools.

The two sided uv protected surface offers advantages in economical cutting. This product is an excellent choice for roof glazing applications in which water droplets are a hazard such as commercial greenhouses where they can cause crop spoilage and loss of light transmission. Cutting tools for home use depends on its thickness hardness and purpose. This is how we cut lexan for vacuum forming now at sabula tech.

Sand the edges with a fine grade of sandpaper for a smoother surface. Not to hijack this threadim looking at cutting a full sheet 8x4 12 inch lexan into 8 20x20 panels for boat hatch replacementswhat i have at the moment is a circular saw and a 140 tooth blademy plan is to use a pump sprayer with water to keep the lexan cool while cuttingwhat do you all thinkis this doomed to failure. Safety is the primary concern when using cutting tools.