Cutting Copper Sheet Metal

Another tool is a plate shear for cutting slightly.

Cutting copper sheet metal. These problems are common for those of us who dont work with sheet metal every day. But the discs wear down quickly cut slowly and shrink in diameter as you use them. These are all affordable and versatile. For cutting out holes in sheet metal its going to be necessary that you begin with a starter hole this can be formed by using the hammer and chisel method to punch through the metal.

Align the tin snips with the sheet metal. One tool is a foot shear or a jump shear. For higher gauges meaning thinner copper you can easily do it with standard hardware store metal snips. Do not use a woodcutting blade as this will ruin the teeth.

Tin snips are primarily used for cutting thin sheet metal like tin aluminum brass and thin gauge. To cut metal with a scroll saw the first thing you need to do is make sure you have the right blade. They look like big scissors and work the same way. Align the snips with the line you want to cut with the upper blade of the tin snips touching the sheet metal.

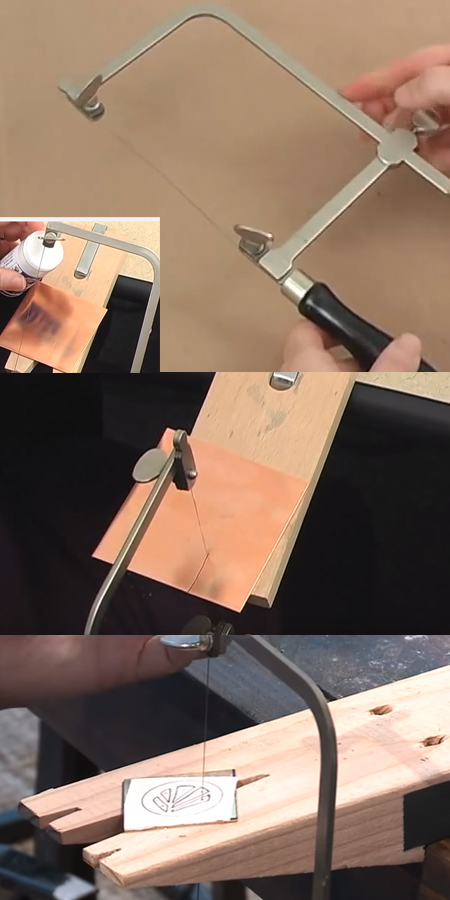

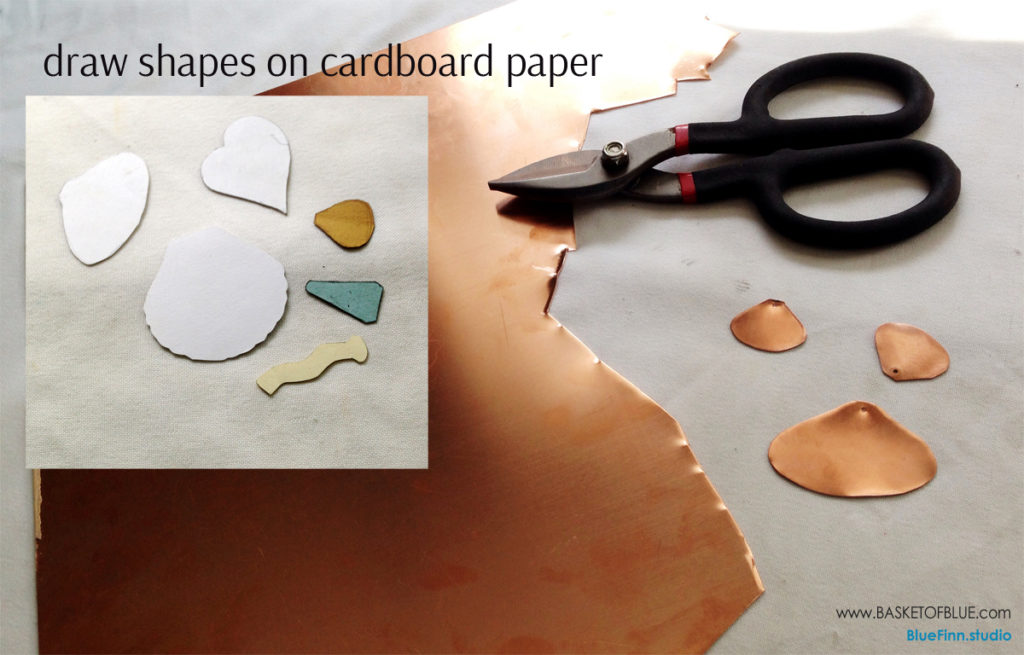

But you dont have to be a tinsmith to cut sheet metal successfully. The one exception. Cut your copper sheet. For thicker copper sheet you would want to use a jewelry saw its a bit slower but gives you a nicer finished cutting edge.

An angle grinder fitted with an abrasive metal cutting disc works well to cut all kinds of metal including bolts angle iron rebar and even sheet metal. There are three tools that kevin caron uses a lot to get a precise cut from a thin piece of metal. A quality jigsaw and the correct metal cutting blade will make short work of sheet metal cuts. However that isnt the only thing its.

If you need a straight cut clamp a straight edge to the sheet to act as a guide for the jigsaw footplate. Cutting sheet metal with snips can be tricky and frustrating. Once you have the starter hole work your way out to the desired radius using the correct red or green colored snip. You could use a nibbler metal shears or a hacksaw.

The first thing you should know is that using a nibbler is ideal for a thicker copper sheet. Clamp the sheet metal in place on your work table to hold it in place while you work. Cutting your own copper shapes can be easier than you think. Metal cutting blades have hardened teeth and come in various sizes from the very heavy duty to the fine jeweler blades.

For the home shop any one of these would be sufficient for cutting sheet metal. These are some of the tools that i use to cut sheet metal.