Chisel Bevel Angle

When im done sharpening it these marks will be almost gone.

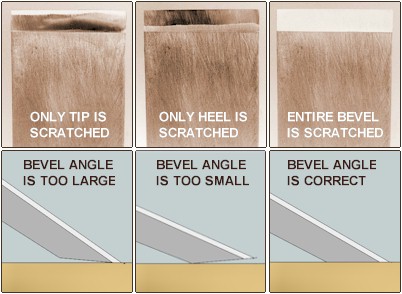

Chisel bevel angle. I like mortise chisels to have a convex curve on the bevel. Its harder to sharpen at the steeper angle or at least i found it harder even though i used the honing guide in my experiments so that i could guaranteed exact angles and used a block of wood charged with polishing compound to prevent back curl normally associated on the strop that creates further increase on the bevel at the actual cutting edge of the chisel that would render the cutting. This chisel is an inexpensive one from a lowes home improvement store. Or more accurately few people hone or whet their edges at that angle 1.

Standard bench and butt chisels are traditionally ground at the factory to 250 and this is fine for most work but the edge will last longer if you add a 50 microbevel to make a 300 cutting angle. The front and back surfaces will become flat and mirror smooth while still keeping this factory ground angle. Use a honing guide to set the bevel angle. Bench chisels the most common have blades about 46 long and can be struck with a mallet.

You can see the grinder marks on the bevel. I use my diamond fret levelers to sharpen chisels. I prefer to set this angle by measuring distances. I grind the bevel on all these chisels at 25o.

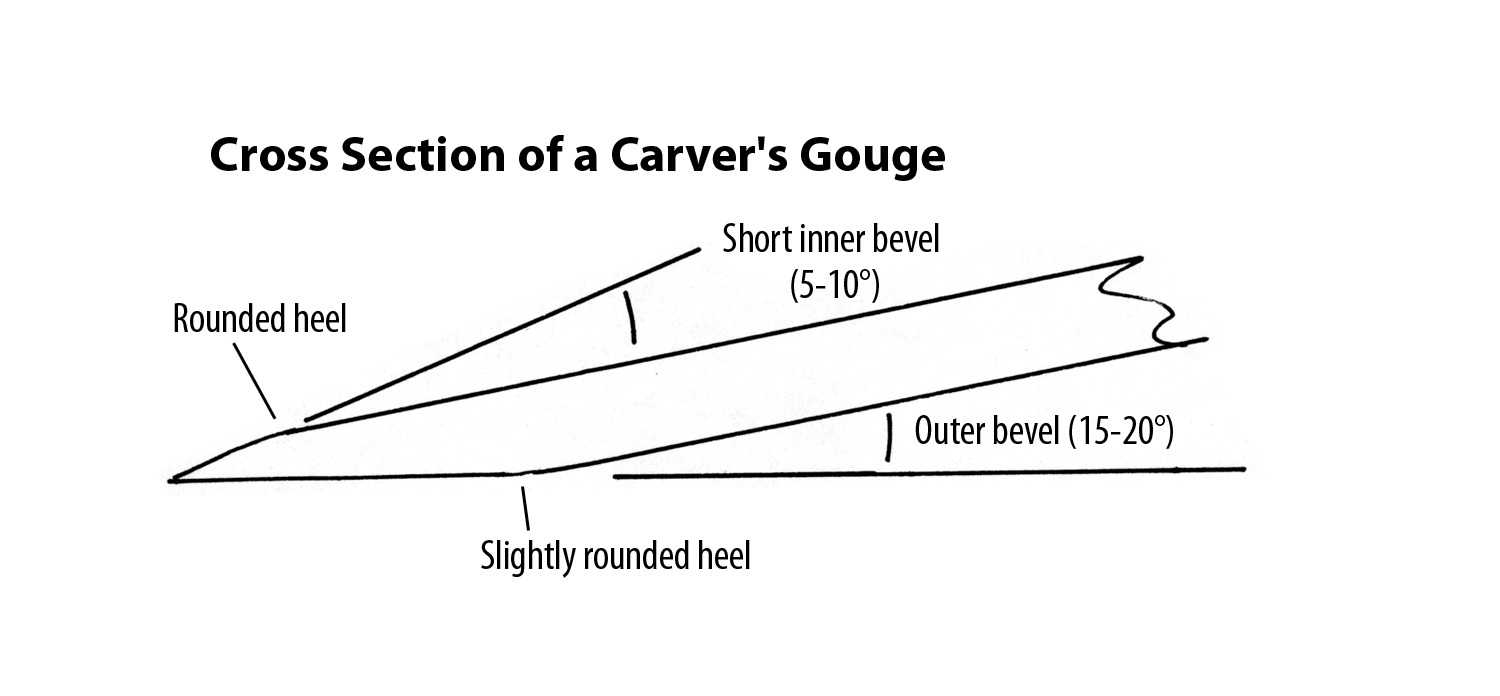

The length of the bevel should be approximately 1 12 times the tools thickness. For a paring chisel the bevel can be as low as 200 some woodworkers like the bevel angle even lower like 150 but you sacrifice edge strength with a bevel that low. They come with blades of either o1 steel a soft grade thats easier to sharpen or a2 a harder alloy that holds an edge longer. Fit the chisel into the honing guide and tighten the screws on either side to hold it in place.

In hardwoods a 20o edge on a chisel just doesnt stand up in any use ive found. Sharpen bench chisels with a 250 bevel angle for best results. 250 is the standard almost universal grind angle for a bevel on plane irons as well as chisels but few people sharpen either at that angle. Adjust the tool rest to grind the same angle as on a conventional skew.

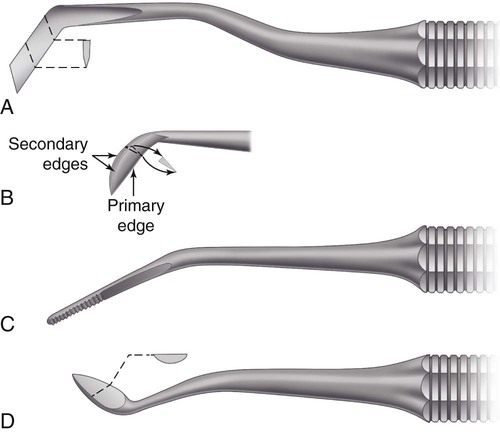

One chisel cant do it all. Switch to a 60 or 80 grit wheel. Don one of my partners prefers to grind and hone at the same angle so he can both high ends of the hollow ground bevel on the stones for more accurate honing. The angle between both bevels will then be 35 to 40 degrees.