Cast Vs Extruded Acrylic Laser

It has a more constant width than cast acrylic and its better suited to being vacuum shaped bent and heated but it can be more susceptible to cracking in some situations.

Cast vs extruded acrylic laser. However some acrylic thicknesses are only available in cast form. Cast and extruded acrylic adapts very well to laser technology and both are an ideal material for laser processing. Furthermore when hot wire line bending drape or vacuum forming cast acrylic sheets are more malleable pliable than extruded acrylic sheet. Laser engraving cast acrylic.

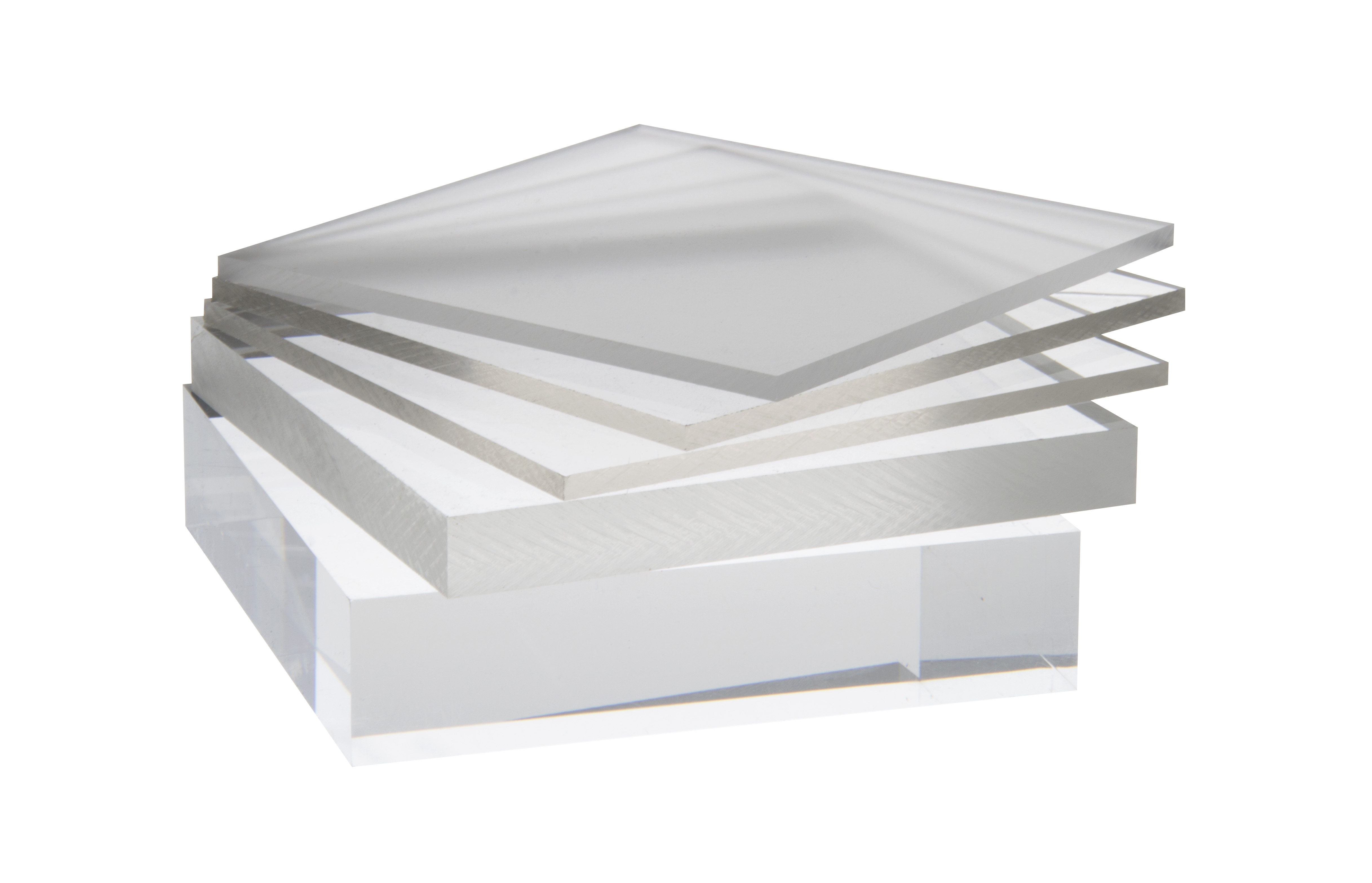

Here is our vp anands take on some of the properties and key differences between cast and extruded acrylic sheets. When laser cutting extruded acrylic there will come a burr on one side of the part. Main difference cast vs extruded acrylic. Acrylic is manufactured in two different methods cast gs or extruded xt and each type will offer its own set of unique properties.

Cast acrylic is used for almost all engraving purposes as when engraved it produces a white frosty look that in contrast to the clear material. Acrylic is manufactured in two different ways. According to their physical properties polymers are divided into three groups as thermosets thermoplastics and elastomersacrylic is a transparent thermoplastic material. Extruded acrylic is factory made in sheets so it tends to be cheap.

Extruded acrylic costs less than cast and is more dimensionally stable meaning the thickness is more consistent across sheets. Also a brief explanation of the differences between cast and extruded clear sheets. The edges on extruded acrylic parts can look a bit different depending on the direction of the acrylic extrusion. Cast and extruded and reacts differently during laser engraving.

In addition cast acrylic when laser cut produce a highly polished edge thus reducing finishing times when fabricating. You can read more about cast and extruded acrylic on our materials for laser cutting page. Why there are two entirely different proc. Extruded acrylic sheets generally have a better thickness tolerance due to the manufacturing process.

On the cast acrylic there is almost no burrs. Polyacrylates such as polymethyl methacrylate. General information about clear acrylic also known by the names of perspex plexiglas pmma and lucite.