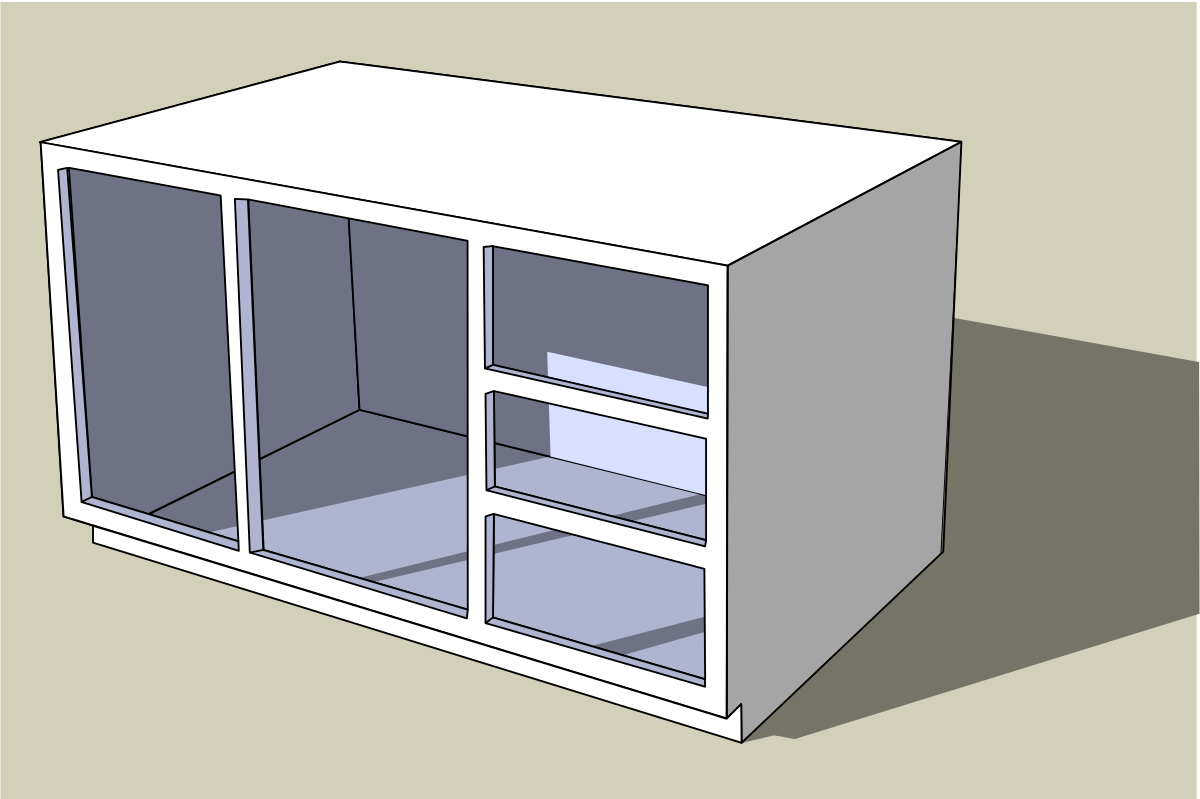

Building Cabinet Face Frames

Face frames cover plywood edges.

Building cabinet face frames. The 3 4 plywood case eliminates panel jointing planing and glue ups. Adjust the bit depth so the cutting edges are only slightly deeper than the face frame. Face frames provide attachment points for door hinge and latch hardware while hiding the front edges of the cabinet box. Trim some face frames flush.

If staining your piece you want to match your face frame wood as closely as possible to your carcass lumber. But its still better to build the face frame a little bigger about 116 in and trim it off with a flush trim router bit. I use wood glue and my k5 kreg jig set for 34 material and use 1 14 coarse thread pocket hole. Trim some face frames flush.

Our trailers are built out of baltic birch plywood and these solid birch face frames blend in nicely. Trim out a cabinet the classic way using pocket screw joints. Face frames on furniture look best when theyre flush with the cabinet sides. How to build and attach a cabinet faceframe build faceframe.

Face frames on some furniture look best when theyre flush with the cabinet sides. Quick and easy way to make and attach a face frame to a cabinet using pocket hole screws and glue. The sample base and wall cabinets shown below have these features to make building them as simple as possible. I generally always build my face frames out of 12 poplar when painting.

In this video we show you how we build the face frames for our custom cabinet option. The faceframe is assembled using pockehole screws and attached to a cabinet with glue and clamps. But its still better to build the face frame a little bigger about 116 in and trim it off with a flush trim router bit. They can also help correct minor plywood bowing and give you a means of fitting one cabinet against its neighbor.

/how-to-build-cabinets-3537068_3_final-5c659a0846e0fb00011169c9.png)