Box Joint Box Plans

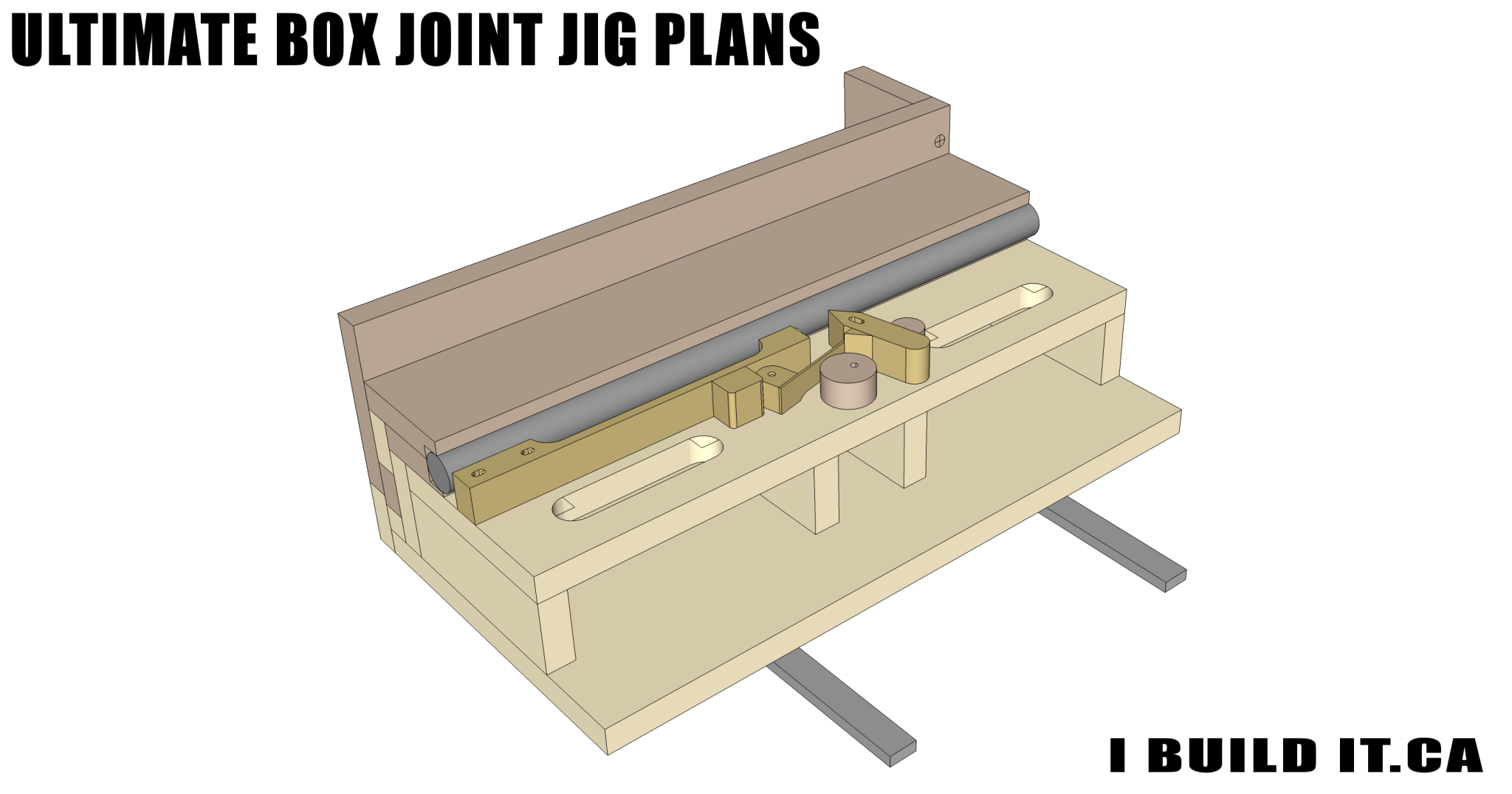

Basic box joint jigs like this one have been around for a long time.

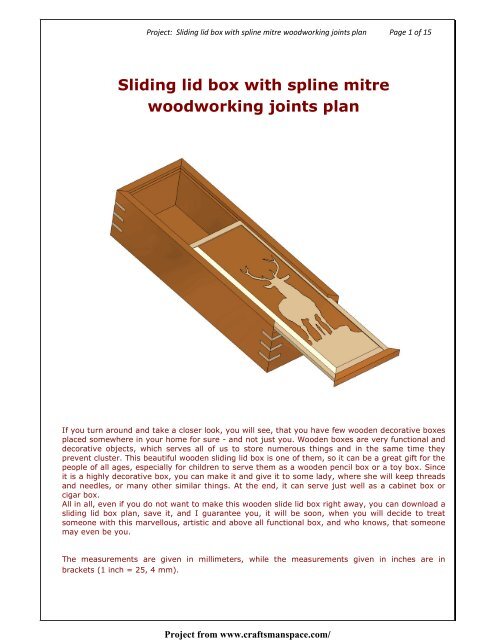

Box joint box plans. Box joints are a strong sturdy and attractive alternative to dovetail jointswhile a through dovetail joint is stronger than a box joint its also more complicated to create. Strong great looking and quickly made box joints are an especially good choice when you have a large number of items to produce. The most impressive thing about this box joint jig isnt the tight fitting joints you can make with it. By tim johnson.

Otherwise using a stacked dado blade set put the blades and cutters together to achieve the desired width of cut and cut a series of tests pieces before cutting into your good stock. To use this jig you will need a tablesaw stackable dado set and a calipers with dial or digital readout. Tablesaw box joints a shop made jig with micro adjust guarantees perfect joints. Our shop made table saw box joint jig is simple to make and easy to use.

The secret is a built in. Box joints are the savvy woodworkers alternative to dovetails. This jig on the other hand can be set up in a matter of minutes. By using shop scraps we got the cost down to zero and came up with a method that makes the box sides interchangeable for foolproof assembly.

I think i may have just done it. Free box joint jig woodworking plan waiting until the price is right to acquire a box joint jig. In this set of free woodworking plans learn how to. After all thats what you expect from a precision made jig.

Most box joint jigs require an almost endless amount of tweaking. However as youll see in the following steps a perfectly fitting clean box joint is easy to create very quickly with a simple box joint jig for your table saw. After you finish building and adjusting the jig learn how get the most from it. In all likelihood you have enough scrap in your shop right now to build it.

Joints sbox8 that will simplify cutting 14 or 38 tongues and sockets or use a router mlcs woodworking box joint router bit 12 shank to cut joints in stock up to 12 thick and 2 wide. Whats really unique is how quickly and easily it can be adjusted.