Babbitt Metal Bearing

Melted babbitt metal must be handled very carefully particularly if there is a chance of exposure to moisture.

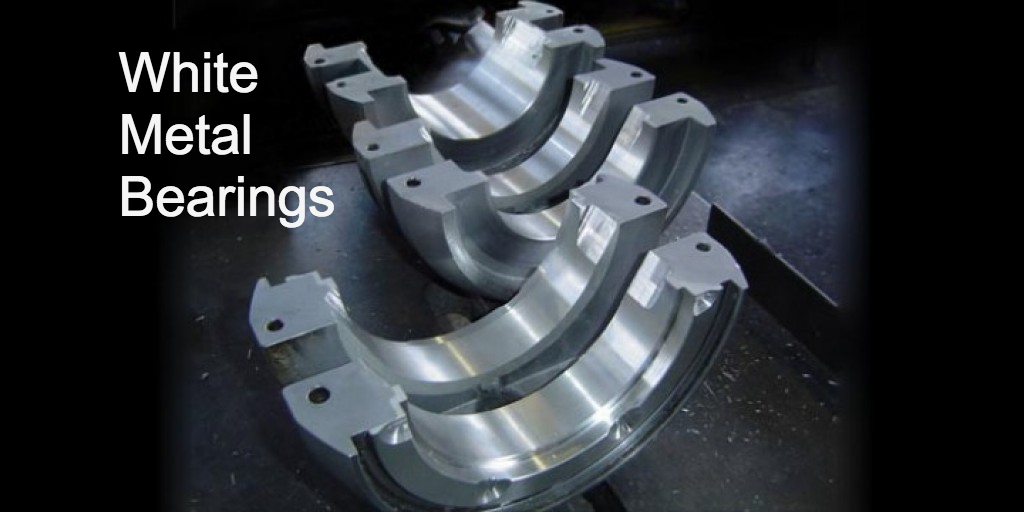

Babbitt metal bearing. Modern babbitts provide a low friction lining for bearing shells made of stronger metals such as cast iron steel or bronze. Splashes of melted babbitt metal will cause severe injury and may be an ignition hazard. Like other terms whose eponymous origin is long since deemphasized. Soft metals such as tin and lead were unsuccessfully tried in the 1700s.

The original babbitt alloy was invented in 1839 by isaac babbitt in taunton massachusetts united stateshe disclosed one of his alloy recipes but kept others as trade secrets. It has properties that help reduce friction which make it a good material to use in a plain bearing. There is no doubt that if a bearing be highly loaded in relation to its size a high tin alloy is desirable. Grades 1 2 3 and 11 are cast in a 34 x 15 x 4 ingot and weigh approximately 1 pound.

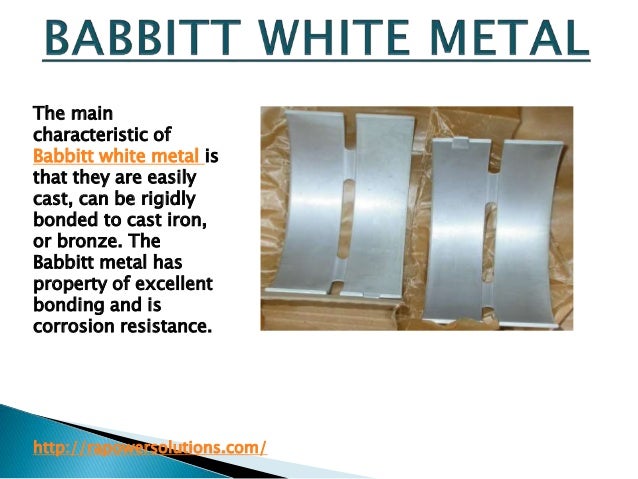

The moisture will create an instant steam explosion that will splatter the molten babbitt metal. Depending on a variety of factors including surface speed of the shaft load bearing and cooling facilities we will help you to select the babbitt metal that is custom fit to your requirements. Isaac babbitt created the babbitt metal in 1839. Babbitt metal also called white metal is a soft white non ferrous alloy used to provide a bearing surface.

Babbitt metal or bearing metal is any of several alloys used for the bearing surface in a plain bearing. The bearing surface is sacrificed with babbitt actually becoming the lubricant and the shaft surface is preserved in case there is a loss of lubrication or other operating anomaly. Other formulations were developed later. The use of bearing materials to reduce bearing friction can be traced at least back to the roman chariot days.

But it was not until 1839 that isaac babbitt patented a bearing with a steel or bronze shell lined with a tin base alloy. Its properties helped reduce friction. This soft non ferrous white alloy later became used to produce the bearing surface. The other grades of babbitt alloys are cast into bar shaped ingots that are approximately 8 34 x 1 x 2 and weigh anywhere from 35 to 5 pounds exact weight depends on the alloy.

Babbitt was known as an inventor and quickly received his patent for this new alloy. Babbitt bearing alloys are the most popular alloys in use today. Babbitt metal also spelled babbit metal any of several tin or lead based alloys used as bearing material for axles and crankshafts based on the tin alloy invented in 1839 by isaac babbitt for use in steam engines. White metal bearing alloys babbitt metal lead and tin based bar shape ingot margash pig dimensions 10 34 x 2 x 1 14 l x w x h 26 x 2 x 1 12 l x w x h.

History of the babbitt bearing.