Woodshop Dust Collection Ductwork

Coming in two.

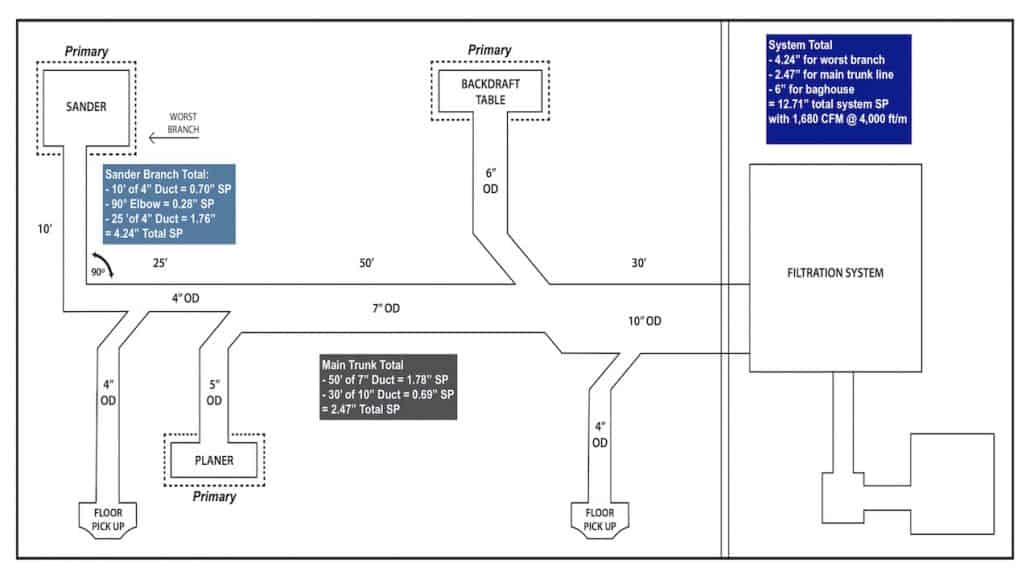

Woodshop dust collection ductwork. A good system however will keep the broom and your lungs from wearing out prematurely. Next find the diameter for your systems main and branch ducts. The speed of air movement through a dust collection system is critical. Many dust collection systems suffer due to poor ductwork designs.

In reality proper pipe sizing can get complicated and depends on many variables. If you have made an investment in a powerful dust collector that is a great first step toward creating a healthy shop environment. For systems carrying woodshop dust and chips engineers recommend minimum air velocity of 4000 fpm in branch lines thats about a 45 mph breeze and 3500 fpm in the main ductthe speed of the air moving in the system may exceed these figures but. Tool size air requirements length of pipe run required number of machines running at one time etc.

Even the best dust collection system wont eliminate the need for occasional sweeping. Rocklers options for metal ducting are the perfect choice. Nordfab is a do it yourself clamp together dust collection ductwork system that you can customize to fit your space. Most cyclones have intake ports of 6 to 8 and some two bag collectors have 5 or 6 diameter intakes so consider at least a 5 main duct.

First figure out the air volume requirements of the machines in your shop see the chart on p. Nordfab ducting makes the perfect dust collection pipe. It is the dust collectors job to overcome the ductwork resistance and pull the proper amount of cfm when you open a branch or branches in a central dust collection system. If you have seen kids trying to drink a soda.

Instead look at the intake port sizes for the collectors youre considering. Do use the largest ductwork that fits your collector. Part 3 of this series shows highlights and selected tips and tricks for working with pvc pipe in a dust collection network. When you drink a soda with a regular straw it does not take much effort.

The nordfab company nordfab is an industrial dust collection solution company that offers dust collection design engineering and products to outfit your small hobby shop to your large. Installing your own dust collection pipe saves you money over costly design and installation expenses. Simple approach for dust collection ducting april 4 2012 by paul mayer filed under shop improvement skill building stationary power tools safety. There is a large amount of misinformation about what the proper size pipe is to run.

There are two main points to consider when choosing a dust collector. Tapered reducers like.