Types Of Lathe Mandrels

Expanding mandrels are the ideal solution to various internal clamping problems.

Types of lathe mandrels. Making and using various types of lathe workholding mandrels. Mandrels for work holding on the lathe harold hall. Link to banggood micrometer httpsgooglscdvr6 just exactly what are lathe mandrels. Examples include live chuck mandrels live bull ring mandrels and dead bull ring mandrels.

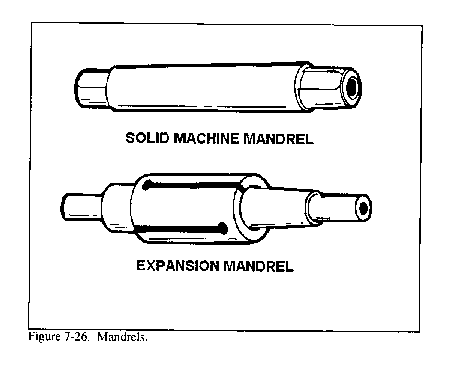

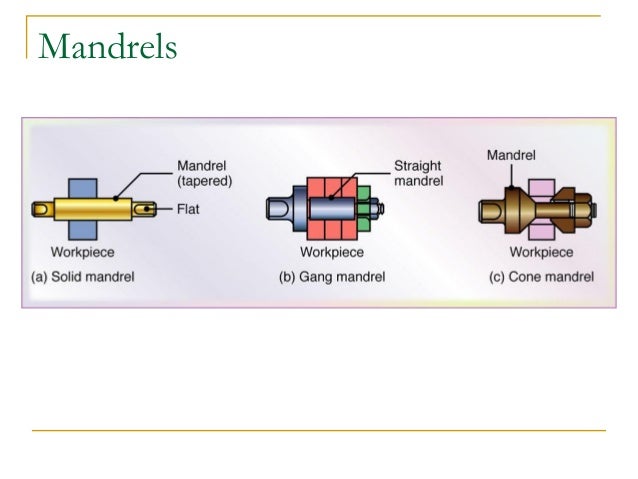

There are many different types of mandrels for specialized applications. Taper shank mandrels are not used between lathe centres. There are several types of arbors for lathes. Taper shank mandrels are generally used to hold small workpieces.

This is some kind of step mandrel the only difference is here a number of equivalent hollow jobs can be machined at a time. Expanding mandrels provide the benefits of versatility and accuracy when compared to other workholding methods. Of the four common methods of work holding used for turning mandrels are by far the most economic invariably made by the user and probably from scrap material. Two common types of taper shank mandrels are.

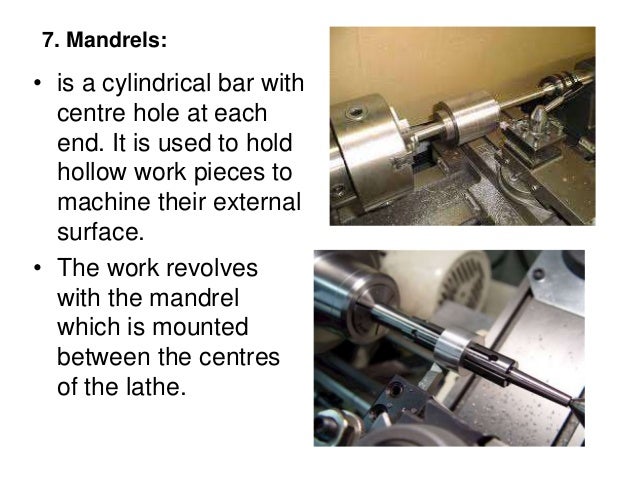

It is used to reduce machining time and generally used in mass production purposes. The construction reduces weight and fits better than a solid mandrel of equal size. A shaped bar of metal which is placed inside a workpiece to be formed eg. For different sizes of holes in work pieces and different mandrels are used.

Collar mandrels having solid collars are used for turning work pieces having holes of larger diameter usually above 100 mm. Arbors used to bend the exhaust pipes for automobiles and in the production of molten glass metal rings threaded rods and furniture legs. Lathe machine is a machine that holds the workpiece on a chuck and tool on a toolpost the lathe machine rotates workpiece about an axis to perform different operations such as turning facing chamfering thread cutting knurling drilling and more with tools that are applied to the workpiece to design an object with symmetry about that axis. A short video of different types of lathe mandrels and some new unique mandrels that i purchased recently.

Other mandrels are clamps that are used by lathes to hold materials during turning operations. They are fitted to the internal taper of the headstock spindle. This is a 4 part video series. Lathes also use mandrels that are set in the center and turned with lathe dogs.

The power operated flange type expanding mandrels can be used on any machine with drawbar facility. Be sure to watch tips 4775 476 4.