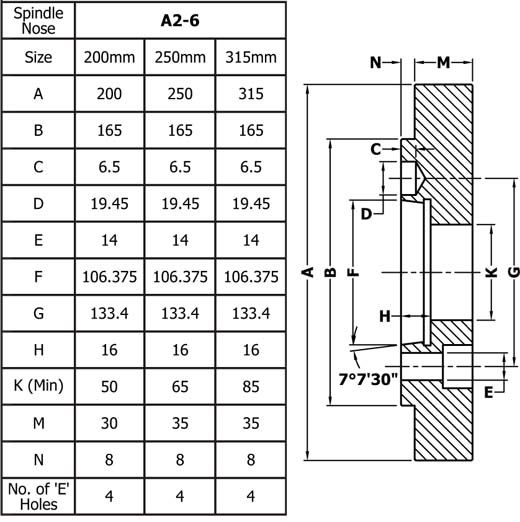

Spindle Nose Standards A2 6

Analyze the corresponding chart and make the required measurements.

Spindle nose standards a2 6. Type d camlock. If your going to engineer some hairy off balance 2 jaw chuck to hang off a spindle regardless of the spindle nose size youll either have to run it at slow rpms or get a baladyne balancing system. It also came with a large face plate that appears to have been made by south bend with a 225 land and 5 threads to the inch. Spindle nose size no.

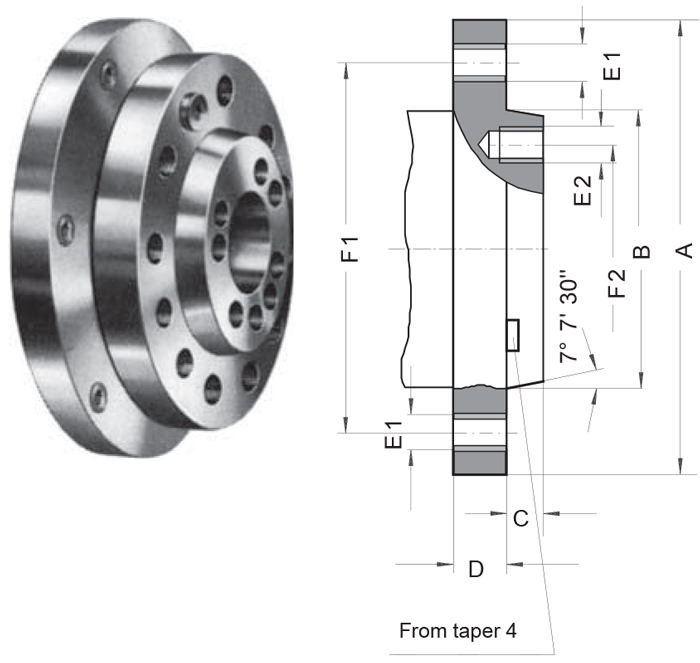

A 2 a 3 a 314 a 30 a 28 12 3key a a 29 a 2 312 taper per ft. Many early horizontal mills had a threaded spindle nose with a non standard coarse thread such as 2 316 6 or 2 516 5. Your a2 8 will go up to 3 stockbore if you get the right spindle nose and collet pad system. Review the diagrams below to determine your spindle nose type.

Spindle nose size type a1 a2 spindle nose size from taper 4 from taper 4 spindle nose size. 20 520 412800 206 476 12x 1 8 unc 4636 a2. Camlock pins are made with a d shape cutout on its body. Tapped holes in flange outer bolt circle without inner bolt circle.

Spindle nose size a b c 0025 d outer bolt circle f1 holes on inner bolt circle f2 e2 inner bolt circle f1 g f2 b1 5 1334 82575 14288 222 11x119 1048 8x 716 14 unc 619 6 1651 106390 15875 254 11x135 1334 8x 12 13. I suspect this one is for a milling machine. American standard spindle nose data source. Select the spindle nose size for your chuck or adapter plate.

Lathe spindle nose identification chart.