Material Surface Feet Per Minute Chart

Spindle speed is not the cutting speed.

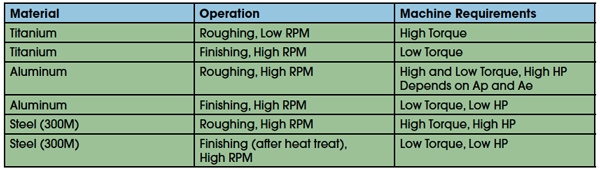

Material surface feet per minute chart. Speeds should be halved when using carbon steel bits and can be doubled for carbide bits. Surface footage chart and formula surface footage theory behind surface feet per minute. This calculates the inches per minute given the chipload per tooth number of teeth and rotations per minute. The following chart reveals ceratizit sacramento formerly promax tools recommendation regarding how many feet your end mill should travel per minute in the material that you are cutting.

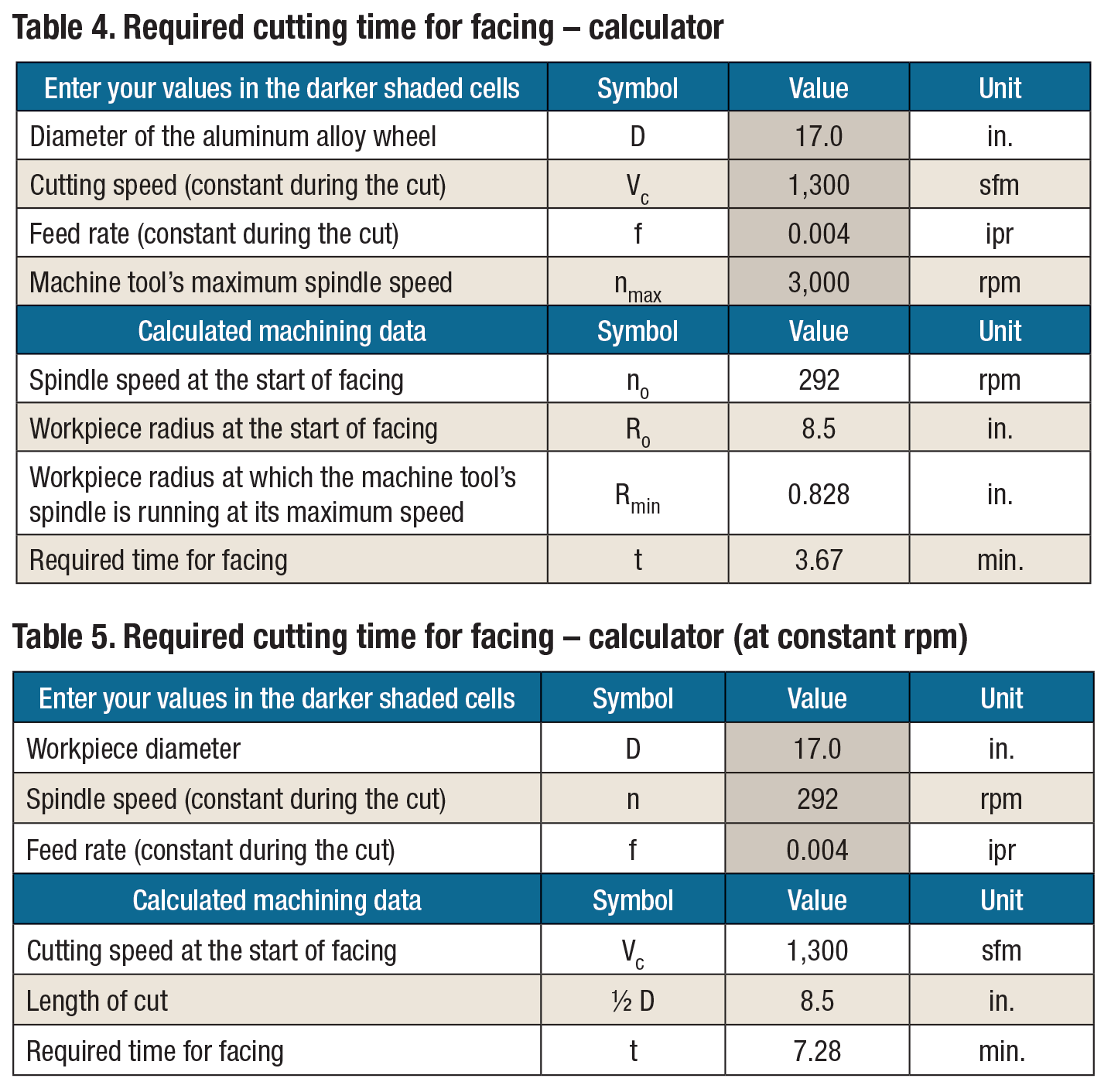

Speeds in surface feet per minute are specified for high speed steel drill bits and are approximate for normal drilling operations. Sfm surface feet per minute rpm revolutions per minute speed ipt inches per tooth chip load ipr inches per revolution. So the optimum is about matching the amount of heat generated by a specific tool and material to the requirements of the tool. Diameter x 314159 pi distance cutter travels every revolution 3.

Surface feet per minute the speed that the tool or the work moves at the point of cut. Distance cutter travels every revolution x 12 distance traveled in feetsf 4. Cutting speed is the speed in linear feet per minute or surface feet per minute sfm that a given tooth flute on the cutter will be moving when it cuts through the material. Every cutter has a diameter 2.

Revolutions per minute calculator this calculates the revolutions per minute given the surface feet per minute and diameter. Chart is recommending how far your cutter should travel per minute in. All materials have a documented sfm or cutting speed. Feet per minute sfm for imperial and meters per minute in metric.

Surface feet per minute sfpm or sfm is the combination of a physical quantity surface speed and an imperial and american customary unit feet per minute or fpmit is defined as the number of linear feet that a location on a rotating component travels in one minute. I explain how cutting speeds are represented in both surface feet per minute and meters per minute. Lathe turning speeds may be increased by 100. Surface speed is measured in linear units per minute.

Spindle rpm sfm dia. X 382 x tooling correction factor. Think of it like a minimum and maximum speed limit on a highway. The faster the surface speed the more heat thats generated.

Ipm inches per minute feed d cutter diameter t number of teeth. Surface feet per minute sfm is the unit of velocity used in machining to identify the machinability ratings of a specific material.