Drill Press Pulley Calculator

Always know what speed your drill.

Drill press pulley calculator. Most does go straight out the sides. Shaft is an odd size and too big for the drill press pulley. This will be your ratio. End of shaft was turned down to 12 i made a fan out of sheet metal and welded it to a collar.

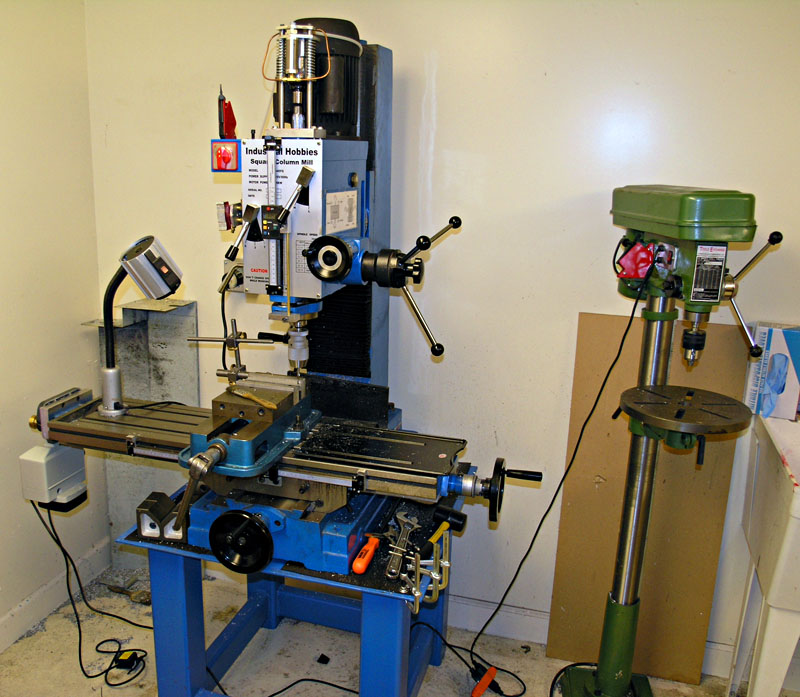

I need a new pulley for my 1940s era drill press but the manufacturer has gone out of business. We are using the low speed to allow the press to cut large holes in metal 1 and larger and also for tapping operations as shown here. For example if your small pulley is 80mm diameter and spins at 1000 rpm and you need to find the second pulley size to spin it at 400 rpm enter pulley1 80 pulley 1 rpm 1000 pulley 2 rpm 400 and. Enter any 3 known values to calculate the 4th if you know any 3 values pulley sizes or rpm and need to calculate the 4th enter the 3 known values and hit calculate to find the missing value.

This kit is only a 21 reduction but rogue fabrication sells kits that go as low as 41. On this episode we get a little in depth on how to change the speed on your drill press and just why we do this. This is easy to follow and anyone can do this. So it was chucked up in the lathe.

One word of advice i would suggest i bought a harbor freight 12 drill press brand new to use this reduction kit on because it uses metric belts that are slightly smaller than 38 i would highly recommend starting off with a drill press with 12 belts as they said on the tech portion of the website. This really pulls a lot of air through the motor. Calculate drill or lathe speed. The readers may find an online calculator that i scripted with php helpful.

New belt sears craftsman drill press model 11324630 113 213 780 113213780. This item v belt pulley 58 124 step 3 4 5 6od mxfans 16mm bore outter dia 54 150mm 5 step a type v belt pagoda pulley belt homeswitch aluminum 16mm bore 4 step a type v belt pagoda pulley belt outer dia 41 130mm. At the hardware store i found a four step pulley of similar size to the original but slightly different in diameter for each step. We remove the pulleys and their protective box to access the head casing underneath find whats wrong.

The bearing worked well with the steady rest. Divide the motor pulley measurement by the measurement of the pulley the belt connects to.